Wednesday, 04 November 2020

The University of Nottingham has cracked the conundrum of how to use inks to 3D-print novel electronic devices with useful properties, such as an ability to convert light into electricity.

The study shows that it is possible to jet inks, containing tiny flakes of 2D materials such as graphene, to build up and mesh together the different layers of these complex, customised structures.

Using quantum mechanical modelling, the researchers also pinpointed how electrons move through the 2D material layers, to completely understand how the ground-breaking devices can be modified in future.

“By linking together fundamental concepts in quantum physics with state-of-the art-engineering, we have shown how complex devices for controlling electricity and light can be made by printing layers of material that are just a few atoms thick but centimetres across. According to the laws of quantum mechanics, in which the electrons act as waves rather than particles, we found electrons in 2D materials travel along complex trajectories between multiple flakes. It appears as if the electrons hop from one flake to another like a frog hopping between overlapping lily pads on the surface of a pond.”

The study, ‘Inter‐Flake Quantum Transport of Electrons and Holes in Inkjet‐Printed Graphene Devices’, has been published in the peer-reviewed journal Advanced Functional Materials.

Often described as a ‘super material’, graphene was first created in 2004. It exhibits many unique properties including being stronger than steel, highly flexible and the best conductor of electricity ever made.

Two-dimensional materials like graphene are usually made by sequentially exfoliating a single layer of carbon atoms – arranged in a flat sheet - which are then used to produce bespoke structures.

However, producing layers and combining them to make complex, sandwich-like materials has been difficult and usually required painstaking deposition of the layers one at a time and by hand.

Since its discovery, there has been an exponential growth in the number of patents involving graphene. However, in order to fully exploit its potential, scalable manufacturing techniques need to be developed.

The new paper shows that additive manufacturing - more commonly known as 3D printing - using inks, in which tiny flakes of graphene (a few billionths of a metre across) are suspended, provides a promising solution.

By combining advanced manufacturing techniques to make devices along with sophisticated ways of measuring their properties and quantum wave modelling the team worked out exactly how inkjet‐printed graphene can successfully replace single layer graphene as a contact material for 2D metal semiconductors.

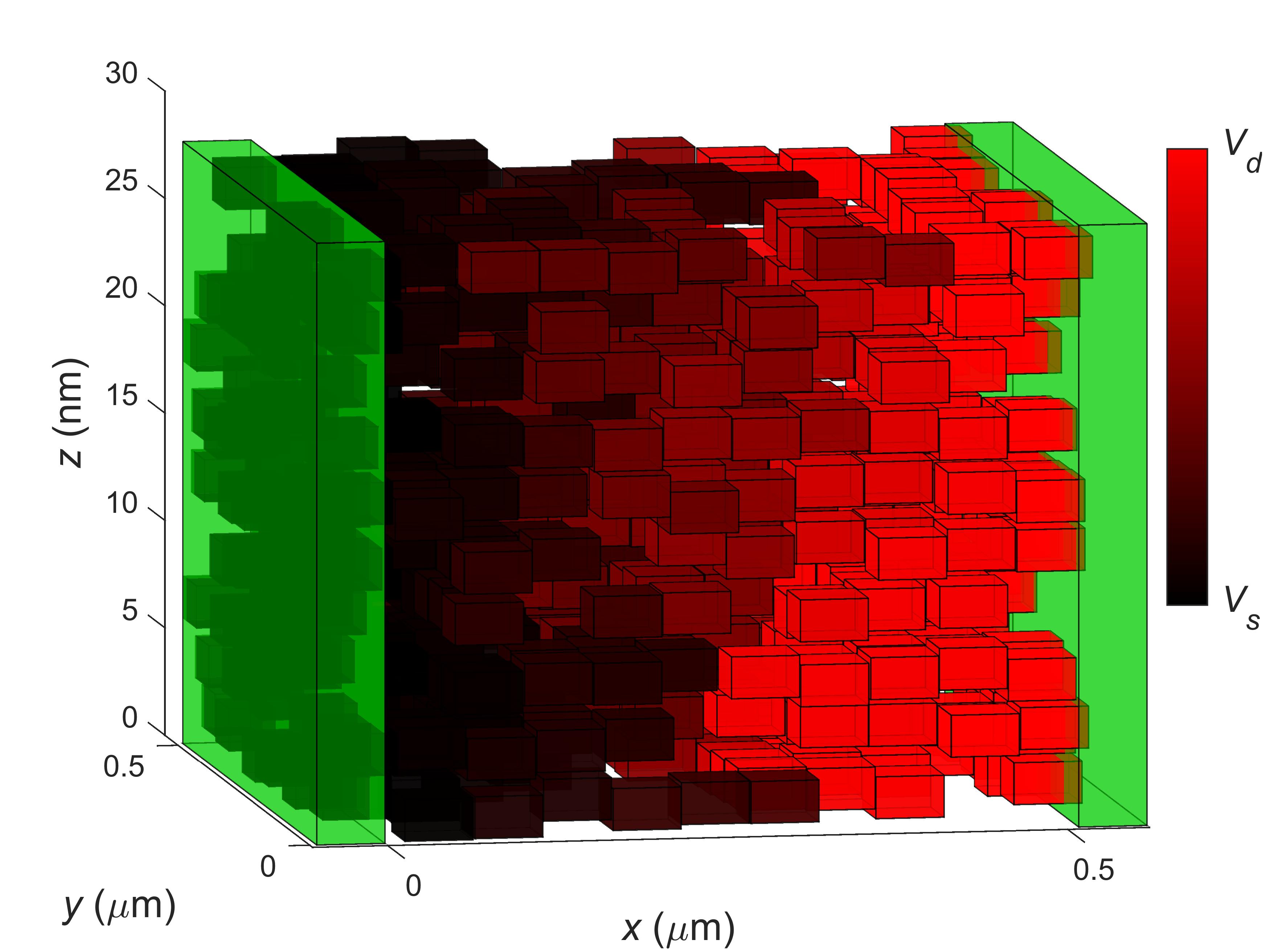

A representative arrangement of graphene flakes in ink-jet printed graphene between two contacts (green). Colour gradient corresponds to variation of flake potentials.

A representative arrangement of graphene flakes in ink-jet printed graphene between two contacts (green). Colour gradient corresponds to variation of flake potentials.

“While 2D layers and devices have been 3D printed before, this is the first time anyone has identified how electrons move through them and demonstrated potential uses for the combined, printed layers. Our results could lead to diverse applications for inkjet‐printed graphene‐polymer composites and a range of other 2D materials. The findings could be employed to make a new generation of functional optoelectronic devices; for example, large and efficient solar cells; wearable, flexible electronics that are powered by sunlight or the motion of the wearer; perhaps even printed computers.”

The study was carried out by engineers at the Centre for Additive Manufacturing and physicists at the School of Physics and Astronomy with a common interest in quantum technologies, under the £5.85m EPSRC-funded Programme Grant, Enabling Next Generation Additive Manufacturing.

The researchers used a wide range of characterisation techniques - including micro‐Raman spectroscopy (laser scanning), thermal gravity analysis, a novel 3D orbiSIMS instrument and electrical measurements - to provide detailed structural and functional understanding of inkjet‐printed graphene polymers, and the effects of heat treating (annealing) on performance.

The next steps for the research are to better control the deposition of the flakes by using polymers to influence the way they arrange and align and trying different inks with a range of flake sizes. The researchers also hope to develop more sophisticated computer simulations of the materials and the way they work together, developing ways of mass-manufacturing they devices they prototype.

Story credits

For media interviews contact Dr Lyudmila Turyanska on lyudmila.turyanska@nottingham.ac.uk or Emma Lowry, Media Relations Manager on emma.lowry@nottingham.ac.uk

Notes to editors:

About the University of Nottingham

Ranked 32 in Europe and 16th in the UK by the QS World University Rankings: Europe 2024, the University of Nottingham is a founding member of the Russell Group of research-intensive universities. Studying at the University of Nottingham is a life-changing experience, and we pride ourselves on unlocking the potential of our students. We have a pioneering spirit, expressed in the vision of our founder Sir Jesse Boot, which has seen us lead the way in establishing campuses in China and Malaysia - part of a globally connected network of education, research and industrial engagement.

Nottingham was crowned Sports University of the Year by The Times and Sunday Times Good University Guide 2024 – the third time it has been given the honour since 2018 – and by the Daily Mail University Guide 2024.

The university is among the best universities in the UK for the strength of our research, positioned seventh for research power in the UK according to REF 2021. The birthplace of discoveries such as MRI and ibuprofen, our innovations transform lives and tackle global problems such as sustainable food supplies, ending modern slavery, developing greener transport, and reducing reliance on fossil fuels.

The university is a major employer and industry partner - locally and globally - and our graduates are the second most targeted by the UK's top employers, according to The Graduate Market in 2022 report by High Fliers Research.

We lead the Universities for Nottingham initiative, in partnership with Nottingham Trent University, a pioneering collaboration between the city’s two world-class institutions to improve levels of prosperity, opportunity, sustainability, health and wellbeing for residents in the city and region we are proud to call home.

More news…