David Sylvester

MetaGate

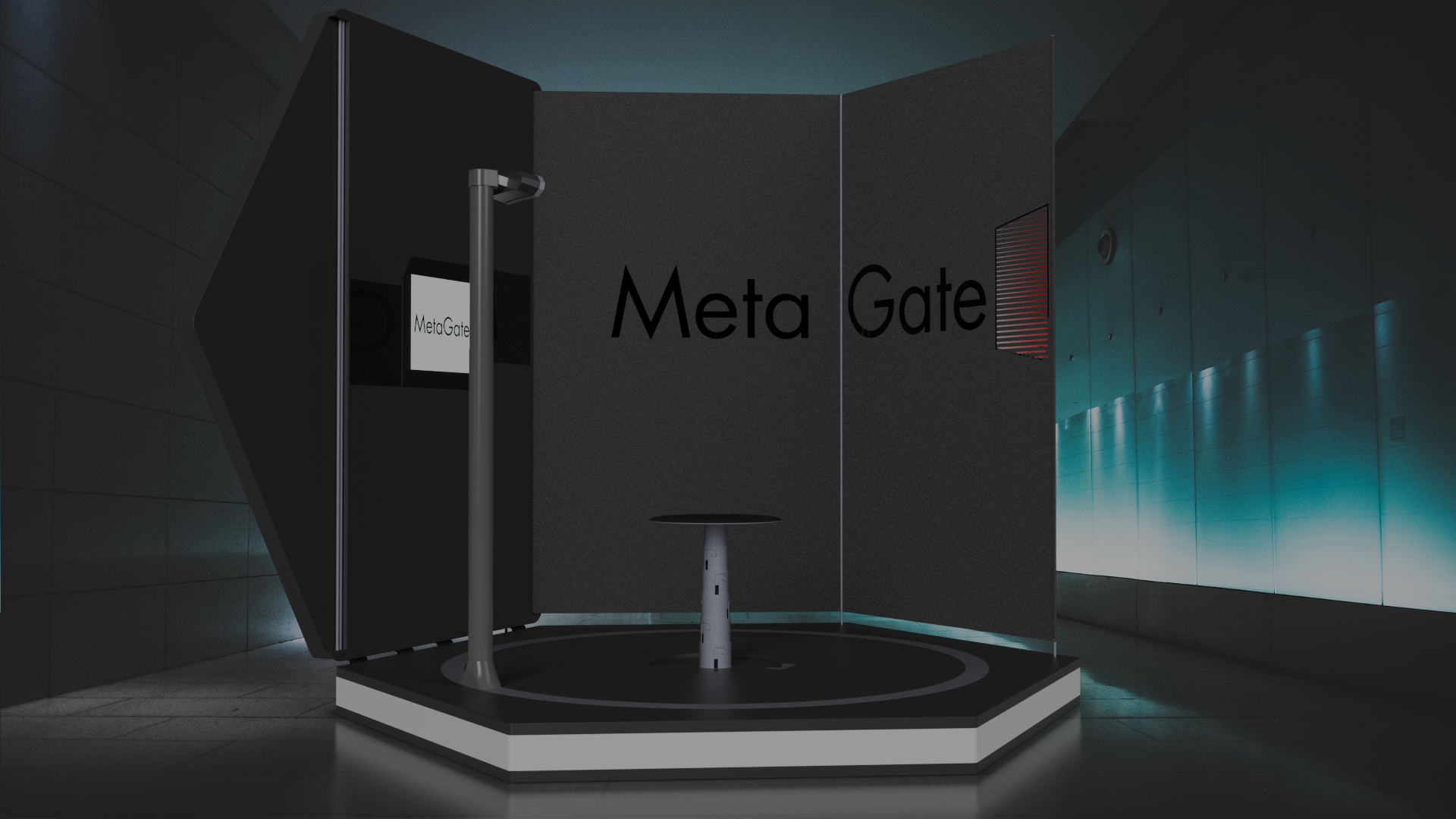

MetaGate is a 3D facial scanning booth targeted at big companies using virtual reality technologies to facilitate hybrid working schemes.

Covid has greatly affected the way we work and demonstrated the potential of working from home at least a few days a week. Big companies like PwC and Nestle have already adopted virtual reality technologies to have employees work in virtual offices and have a more immersive conference call experiences. These office workers are all required to use representative, accurate avatars of themselves as ‘the office’ is a professional setting.

Currently, it is time consuming and expensive to capture accurate 3D data for making avatars to ‘wear’ when in VR. The process requires an expensive, handheld scanner operated by a technician to be manually pointed and moved around the target to build up a cloud of 3D data points. MetaGate solves these problems by providing a mobile, automated 3D scanning booth capable of quickly and reliably taking high quality 3D scans of both a user’s facial geometry and colours.

MetaGate folds down and can be packed away for transport and is intended to be rented by companies for a few days at a time while they create avatars for all the staff in need of them. The product can also be sold directly to people and comes with many colour and branding customisation options.

MetaGate has a touchscreen and mesh rollers mounted in the lid to allow users to operate the booth privately and alone; the rollers can be pulled out to create partitioning walls around the booth for privacy and to reduce the amount of ambient light the scanner has to contend with. The design has an adjustable/collapsible leather bound stool for accessibility and comes with a fold up ramp for wheelchair users.

The scanning unit is mounted on a turn ring that rotates around the user. The Scanner can also be pointed up and down and can be raised or lowered to ensure every angle is scanned. This is all computer controlled and takes around 5 minutes from start to finish.

The scanner itself uses infrared structured light technology to map the users head in 3D space. The infrared emitter projects a grid of infrared light onto the target; the infrared cameras measure the distortions of the grid as they wrap around the target and the normal camera captures colour data. As they build up images from many angles the computer puts together a 3D data point cloud file that can be exported to make accurate full colour avatars.

David Sylvester' designs

Student Biography

I joined the University of Nottingham Product Design and Manufacture course in 2018 with the intention of quickly getting a bachelore and getting into the workforce. I chose PDM "because I liked DT at school" and didn't know what else to do. Four years and a masters degree later, it's clear that not even I knew I enjoyed design so much. PDM and design in general have provided me with so much knowledge and freedom to solve problems my way. There is something incredibly satisfying about being able to take an idea and turn it into a fully working product. The course has equipped me with skills like CAD modelling, image editing and rendering softwares, and greatly enhanced the way I not only solve problems, but approach them in the first place.

I am interested in virtual reality, the metaverse, 3D printing and other emerging technologies, and aim to get involved in one or all of these industries throughout my career. My dream is to be part of a team working with the latest technologies to develop products that have a real and positive impact on people in the world.