Background

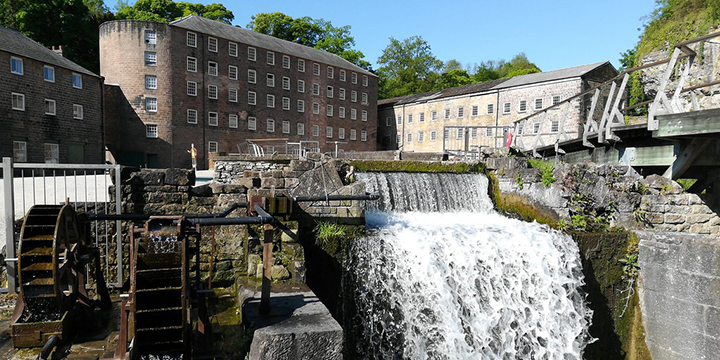

Cromford Mills, in the Derbyshire Dales, is the home of Sir Richard Arkwright’s first mill complex, the birthplace of the modern factory system and internationally recognised as a UNESCO World Heritage Site. The first successful water powered cotton spinning mill was built here in 1771 and the mill now runs as a successful tourist attraction, with a visitor centre, cafes, shops and nature walks.

Opportunity

Cromford Mills was interested in exploring how the still existing original wheel pit might provide a useful and sustainable energy source in the present day.

Cromford Mills existing watercourse and wheels

Solution

After meeting with Simon Gill, Operations Director at the Arkwright Society, Tim Saunders, of the Energy Innovation and Collaboration team, suggested that a University of Nottingham MSc student might find the project of interest as part of their studies. Adam Langan, studying Sustainable Energy Engineering, was identified as the perfect candidate with supervision from Associate Professor Dr Arthur Williams.

Adam started by taking measurements at the site to understand the size of wheel that had existed previously. He concentrated efforts on the wheel pit and watercourse of the second, larger mill constructed in 1776. The building is no longer standing however the wheel pit is still present.

Adam then examined the power source, water, in this case fed from Bonsall Brook. He looked at the catchment area, standardised annual average rainfall and evaporation data to produce an average flow rate. Data from the adjacent River Derwent was scaled down to provide an understanding of the annual plot of flow.

Wheel design was the next factor to be explored with advantages of modern materials and methods to be factored in. Combining the measurements taken, Adam was able to get an idea of the size and type of wheel that was present when the mill was operational. With a wheel pit length of 6.8m the diameter of the wheel would have been around 6.5m to utilise the size of the pit. The radius of the wheel would be approximately 3.25m, with water entering at just above the axle point, which is characteristic of a breastshot waterwheel.

Armed with his results and data Adam was able to calculate the potential power outputs and efficiency of different types of wheels if installed in the existing wheel pit using modern design, materials and methods. He concluded that the original breastshot waterwheel and the overshot waterwheel were the top two contenders for the Cromford Mills site.

Breastshot waterwheel

It is likely that the original wheel was of the breastshot type, a vertical wheel with a horizontal axis suited to large volumes of water.

Water hits blades or driving buckets at a roughly central point, with a disadvantage being that the gravitational weight of water is only used for about a quarter of the rotation of the wheel.

Many wheels of this type were built in the 19th century at mills such as the one in Cromford.

Overshot waterwheel

An overshot waterwheel is positioned so that water enters buckets at the top of the wheel, allowing a high level of efficiency as nearly all of the energy is gained through the weight of the water.

The overshot design is very efficient and does not require a rapid flow of water to operate, meaning that in low water level conditions energy can still be generated. However, the design of these wheels can be complicated and more expensive to construct due to the high head height required for maximum efficiency.

Results

Adam’s investigation was able to show that an overshot waterwheel design could provide an efficiency level of 72%, compared to 66% for the breastshot waterwheel, with an annual power output of 182MWh a year. Adam calculated that the overshot design would give a faster return on investment with a shorter payback period of 4 years as opposed to 9 years for the breastshot design. These results show that the overshot design would be the optimum choice for Cromford Mills.

Carbon savings

A principle aim of the study was to enable Cromford Mills to reduce carbon emissions. The study was able to show that the implementation of a new wheel and production of zero-emission renewable energy could result in a saving of 14 tonnes of CO2 emissions per year for the mill, with the overshot wheel once again proving to be more efficient, saving 1.2 tonnes more than a breastshot design.

Adam commented, “I thoroughly enjoyed the study I conducted on the potential for hydro power at Cromford Mills. I hope my contribution may aid in a future installation of a hydro generation project at this fantastic historic site."

Benefits

The generation of renewable energy at the Cromford Mills site would reduce energy costs and dependence on the grid. It could also have the potential to increase visitor numbers by providing added interest to draw visitors to the heritage site interested in the reinstatement of an updated traditional technology.

Simon Gill commented, “The Arkwright Society is delighted with the report and would like to give special thanks to Adam and the University of Nottingham for providing such useful data to work from.”

Subsequently the Rural Community Energy Fund, a Government funding scheme to support rural communities across England wanting to set up renewable energy projects, was identified as next step funding source for further feasibility work and business planning. A successful bid was made to the fund and work continues.

Support

Cromford Mills received support from the University as part of Energy for Business. Delivered by the Energy Innovation and Collaboration team and funded by the European Regional Development Fund (ERDF).

Contact the Energy Innovation and Collaboration team for an informal chat about the support on offer.

Email: energy@nottingham.ac.uk

Website: www.nottingham.ac.uk/energyforbusiness

Phone: +44 (0) 115 7484969