Multiple Materials

The novel frontier in material science: additive manufacturing of dissimilar materials

Additive manufacturing (AM) offers a new method of fabrication that allows for the precise control of the chemical composition of every volume of material deposited in the final product, through computational materials science techniques. This allows for the creation of functional materials directly from computation. This has the potential to revolutionise many industries that have traditionally relied on traditional manufacturing methods.

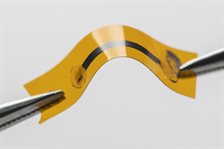

The combination of dissimilar materials in the same volume allows unrivalled design freedom (heterogenous distribution of stiffness, bio-compatibility etc.) and offers material freedom, multiplying the range of material options available today.

Nevertheless, at the core of the success of multi-material additive manufacturing (AM) is a deep understanding of the interactions between different materials at the interface where they meet. Of particular interest is, therefore, the application of modelling and optimisation algorithms to distribute the different materials in the printed parts, to achieve integral interfaces and functionality.

Multi-material research for inkjet 3D printing

One of the areas of research interest at CfAM is the study of functional low-dimensional conductive and insulating materials, which can be used to realise composites for a range of applications, including opto-electronic devices, probes for medical imaging and nanomedicine. Research studies include the synthesis and the inkjet 3D printing of perovskite nanocrystals, graphene and graphene based heterostructures as well as insulating materials (boron nitrade, etc.).

3D printing of personalised tablets

Inkjet 3D printing of drugs can also involve the use of multiple materials in a single print job. This can allow for the creation of more complex and customizable tablets with tailored drug release profiles. For example, different regions of the tablet can contain different active ingredients, or a dissolvable outer layer can surround a slower-dissolving core.

Multi-material printing allows for the creation of functional devices with active ingredients encapsulated in a specific way that can be used for patient-specific drug delivery, increasing the bioavailability of the drug and reducing the side effects.

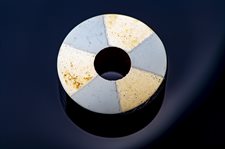

Multi-material research for metallic AM

Research on Functionally Graded Materials (FGM) is one of the core activities at CfAM. FGM are materials that have a gradual and continuous variation of one or more properties over their volume. In the case of metallic materials, FGMs can have variations in properties such as composition, microstructure or density of the materials. Graded structures based on the use of dissimilar metallic materials are now applied in several advanced components which require extreme thermal management, combination of strength and corrosion resistance. Current possibilities are however limited to the production of geometrical axially symmetric components and the poor chemical control (mainly restricted to 1-dimension) with negative implications on material design and feedstock re-use. To enable true deterministic control of chemical gradient in 3D research, research at CfAM is focusing on the development of new drop on demand of high-temperature metal jetting technique (photo) as well as different multi-material laser powder bed fusion (photo) as well as a novel hybrid technique that will combine inkjet 3D printing and laser powder bed fusion. *how to present photos?