Advanced Manufacturing

The HFRG has been involved in understanding human factors in manufacturing for over 20 years.

In particular, our research aims to optimise manufacturing systems for individuals and teams, as well as industrially-produced products for end users.

Our work has informed the development of advanced technologies which have been implemented in OEMs and SMEs

Our research is underpinned by long-standing expertise in Human Factors, with a multidisciplinary team drawing from industrial design, engineering, psychology, human-computer interaction and computer science.

Examples of our work include:

- research into virtual reality systems for reducing cost in automotive design processes;

- supporting the collaborative work of co-located and distributed engineering and design teams (through technology and organisational interventions), developing and testing haptic feedback for improving spatial understanding in virtual environments;

- understanding multisensory virtual environments for health and safety training;

- testing virtual training environments for automotive service and assembly tasks;

- investigating trust in virtual reality;

- and developing cloud-based systems to support design and manufacturing activities.

Projects

CloudiFacturing

Title: CloudiFacturing

Funder: EU Horizon 2020 - Grant No. 768892

Total value: £242,985

Start to end date: 1 September 2017 – 31 March 2021

Summary:

The cloudification of services has become the ideal enabler in the manufacturing digitalization. Successful European initiatives such us CloudFlow, CloudSME or Fortissimo have demonstrated the benefits of cloudifying engineering services, by combining HPC resources, computational tools, and cloud computing platforms.Manufacturing SMEs are empowered to compute and solve problems that cannot be tackled without Cloud and HPC technology, making them more competitive by reducing development times for innovative products with better performance. The results of these initiatives are fostering the engineering and to some extend the prototyping processes within the manufacturing workflow. However, monitoring and optimizing production processes have not yet greatly benefited from an integrated information workflow and simulation loop based on online factory data.

This project aims to consolidate two existing open cloud platforms (CloudFlow and CloudSME) and extend their capabilities to leverage the link between online factory data and simulation of engineering processes.The core partners of CloudFlow and CloudSME are joining forces to leverage factory data with cloud-based engineering tools:

- paving the way toward manufacturing analytics and digital twins,

- enriching the manufacturing engineering process with on-line data

- simulating and optimizing producibility and production processes with the vision to support it in real-time

Network Plus: Industrial Systems in the Digital Age

Title: Network Plus: Industrial Systems in the Digital Age

Funder: EPSRC research grant EP/P001246/1

Total value: £1,003,590

Start to end date: 01 September 2016 – 31 August 2019

Summary:

The Network Plus: Industrial Systems in the Digital Age is funded by the EPSRC Manufacturing the Future challenge theme, addressing the area of Digital Manufacturing. There is a particular focus on ensuring that challenges addressed within the Network Plus are driven by the current and future industrial context. The Network Plus is bringing together core colleagues from the Manufacturing, ICT, Digital Economy, Design, Human Factors and Business communities to build new collaborations between leading academics and industry partners. It will:

- Identify relevant elements from these existing activities to conduct international benchmarking and establish the UK lead in specific elements of relevance to Future Industrial Systems in the Digital Age;

- Enhance cross-sectorial learning and fertilisation; and

- Identify new, discipline-bridging, agenda-setting opportunities for feasibility studies leading to scientific insight and future platforms and funding applications from national and international funders.

Sensory illusions using low-cost haptic devices to enhance spatial understanding for engineering design

Title: Sensory illusions using low-cost haptic devices to enhance spatial understanding for engineering design

Funder: EPSRC - EP/N00549X/1

Total value: £239,566

Start to end date: 1 December 2015 – 31 August 2017

Summary:

This project will research the use of strategically-positioned, easy to wear, vibrating devices for improving engineers’ understanding of 3D spaces in virtual environments. The system will use low-cost technologies and support day-to-day engineering design work.

Currently, the majority of engineering design is conducted on desktop systems. These do not allow engineers to experience the 3D spaces they are designing, thus limiting design success in applications with human users, such as component access routes for assembly and reach investigations for a manufacturing line.

Engineering for users currently relies mainly on physical prototypes, which are expensive to produce and may not reflect current design intent due the time taken to build them. Digital human modelling, in which CAD representations of humans are used for ergonomics investigations, offer some benefits but are not suitable for complex motions and do not provide subjective responses. Design solutions can be viewed and experienced in virtual reality such as CAVEs, but depth perception in virtual environments can be inaccurate, leading to rejection of this technology by engineers, or unsound decision-making. Moreover, CAVEs are expensive and gaining access to them can be difficult for engineers conducting everyday design and analysis work.

This project will determine whether a small number of worn haptic (sense of touch) devices can improve spatial awareness in virtual environments.

Key publications:

Lawson, G., Roper, T., and Abdullah, Z.C. (2016). Multimodal “sensory illusions” for improving spatial awareness in virtual environments, In Proceedings of the European Conference on Cognitive Ergonomics 2016

EPSRC grant details

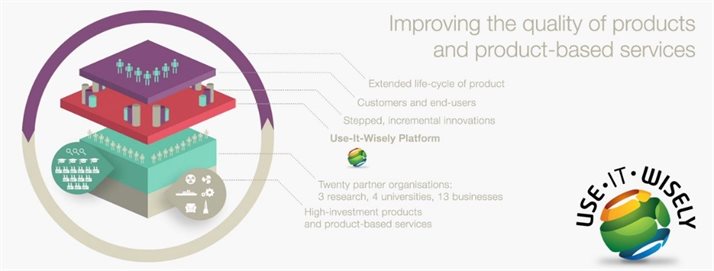

Use-it-Wisley: Innovative continuous upgrades of high investment product-services

Title: Use-It-Wisely: Innovative continuous upgrades of high investment product-services

Funder: European Commission Framework Programme 7 (NMP-FoF-609027)

Total value: €6,440,000

Start to end date: September 2013 – November 2016

Summary:

In the past, customers invested in high cost, long service-life products. Today, they demand complex product-services capable of adapting to new customer goals and rapidly changing markets. The Use-it-wisely project will enable European manufacturers to operate successfully within this new paradigm.

The project will investigate a new business model that implements continuous product-service adaptation through a sequence of small innovative steps. It will demonstrate that product-service agility and extended service life realized in this way is more viable than large and infrequent upgrades in terms of cost, duration and environmental impact.

Use-it-Wisely will develop and demonstrate the adaptation platform consisting of the following three elements: (1) multi-disciplinary actors-product-service system model; (2) adaptation mechanism based on the knowledge and skills of all actors involved with the system; (3) interactive collaborative distributed environment, where the actors work out the adaptation steps. The scientific breakthrough will be achieved by creating and validating a holistic systems engineering structure that combines human-machine systems, product lifecycle management, business and organizational dynamics and lifecycle assessment.

The industry-led consortium is founded on complementary clusters in six key industry sectors: energy, machinery, space, office workplace, vehicles, and ship building. Use-it-wisely will enable new business for the manufacturers and their suppliers, subcontractors and open new opportunities for the customers. It will increase their competitive advantage by means of product-service agility, lower costs, shorter lead times, and reduced environmental impact. Finally, it will help to transform people’s knowledge and skills into product-service value thus strengthening Europe’s global competitiveness and securing domestic employment. With Use-it-wisely, the more the product-service is used, the better it gets.

Project partners:

- Teknologian Tutkimuskeskus Vtt, Finland

- Tecnatom S.A., Spain

- Universidad De Malaga, Spain

- Metso Minerals Oy, Finland

- Rd Velho Oy, Finland

- Thales Alenia Space Italia Spa, Italy

- Advanced Logistics Technology Engineering Center Spa, Italy

- Vastalla Srl, Italy

- Volvo Technology Ab, Sweden

- Chalmers Tekniska Hoegskola Ab, Sweden

- M. Moschatos - K. Stratis Oe, Greece

- International Naval Surveys Bureau, Greece

- Naytiliakes Metaforikes Kai Epikoinoniakes Epixeiriseis Seability Etaireia Periorismenis Euthinis, Greece

- Institute Of Communication And Computer Systems, Greece

- Nederlandse Organisatie Voor Toegepast Natuurwetenschappelijk Onderzoek Tno, The Netherlands

- Gispen International Bv, The Netherlands

- Berner Fachhochschule, Switzerland

- C.C.I.C.C. LIMITED, Ireland

- Hermia Business Development Ltd, Finland

Key publications:

Langley, A., Patel, H. and Houghton, R. (2017). Fostering a Community of Practice for Industrial Processes. Chapter 10. In: S.N. Grosser, A. Reyes-Lecuona and G. Granholm (Eds), Managing the Upgrading Dynamics of Long-life Assets -Engineering and Business Approaches.

Use-it-Wisely

European Commission CORDIS: Use-it-Wisley Innovative continuous upgrades of high

investment product-services

CloudFlow: Computational Cloud Services and Workflows for Agile Engineering

Title: CloudFlow: Computational Cloud Services and Workflows for Agile Engineering

Funder: European Commission Framework Programme 7 (NMP-ICT-FOF-609100)

Total value: €8,788,949

Start to end date: July 2013 – December 2016

Summary:

CloudFlow the ambition to provide a Cloud Computing infrastructure based on existing technology and standards that allows SME software vendors to offer current and future customers (being it SME or bigger companies) new cloud services along and across the engineering and manufacturing chain - even vendor independent. CloudFlow covers Computer Aided Design and Manufacturing (CAD/CAM), Computer Aided Engineering (CAE), especially. Computational Fluid Dynamics (CFD) including pre- and post-processing, simulation of mechatronic systems (Functional Digital Mock-Up – FDMU) and Product Lifecycle Management (PLM) including data archival.

Key publications:

Borsci, S., Lawson, G. and Broome, S. (2015) Empirical evidence, evaluation criteria and challenges for the effectiveness of virtual and mixed reality tools for training operators of car service maintenance. Computers in Industry, Volume 67, February, 2015, pp 17 -26 (http://www.sciencedirect.com/science/article/pii/S0166361514002073)

Cloudflow

European Commission: Computational Cloud Services and Workflows for Agile Engineering

LARTE - Live Augmented Reality Training Environments

Title: LARTE - Live Augmented Reality Training Environments

Funder: Innovate UK – 101509

Total value: £308,643

Start to end date: 2013-2015

Summary:

LARTE Project was initiated to investigate and challenge the effectiveness of traditional training and learning environments and methodologies, creating new configurable - dynamic environments that will transform the way engineering staff are train and developed.

The goal of the project was to develop a prototype software solution, to prove out the ability to create Virtual and Immersive training environments that support the learning of infrequent tasks. These environments could become commonplace in industry to accomodate increasing customisation in future widescale manufacture. The project brought together the Human Factors research skills of The University of Nottingham with the visualisation technology, expertise of Holovis and the extensive data and use case provided within manufacturing and service environments of Jaguar Land Rover.

Key publications:

Borsci, S., Lawson, G. and Broome, S. (2015) Empirical evidence, evaluation criteria and challenges for the effectiveness of virtual and mixed reality tools for training operators of car service maintenance. Computers in Industry, Volume 67, February, 2015, pp 17 -26 (http://www.sciencedirect.com/science/article/pii/S0166361514002073)

Borsci, S., Lawson, G., Jha, B., Burges, M. and Salantri, D. (2016) Effectiveness of a multidevice 3D virtual environment application to train car service maintenance procedures. Virtual Reality, March 2016, Volume 20, Issue 1, pp 41-55 (http://link.springer.com/article/10.1007/s10055-015-0281-5)

Research Councils UK project details

VISTRA: Virtual Simulation and Training of Assembly and Service Processes in Digital Factories

Title: VISTRA: Virtual Simulation and Training of Assembly and Service Processes in Digital Factories

Funder: European Commission Framework Programme 7 (ICT-285176)

Total value: €5,336,798

Start to end date: September 2011 – August 2014

Summary:

Virtual training systems show a high potential to complement or even replace physical setups for training of assembly processes in and beyond the automotive industry. The precondition for the breakthrough of virtual training is that it overcomes the problems of former approaches. One key challenge to address when developing virtual assembly training is the extensive authoring effort for setting up virtual environments. Although knowledge from the product and manufacturing design is available and could be used for virtual training, a concept for integration of this data is still missing.

VISTRA aims at the design of a platform which transfers available enterprise data into a unified model for virtual training and thus enables virtual training of workers before the physical prototypes exist. A second hurdle for virtual training is the poor user acceptance, mainly related to dissatisfying interaction concepts. In this context, VISTRA introduces an innovative hardware set-up for game-based user interaction, which has been chosen to enhance user involvement and acceptance of virtual training. Another deficit of existing virtual training solutions is the incapability to simulate the physical behaviour e.g. of flexibles parts. Here, VISTRA will develop suitable techniques for the integration and real-time simulation of complex, flexible parts in virtual training.

Key publications:

Gorecky, D., Lawson, G., Mura, K., Hermawati, S., Overby, M. L.

User-centered Design of a Game-based, Virtual Training System. In: Conference Proceedings. International Conference on Applied Human Factors and Ergonomics (AHFE-2012), July 21-25, San Francisco, CA, United States, AHFE, 2012

Gorecky, D.; Lawson, G.; Mura, K.; Hermawati, S.; Overby, M. L.

User-centered Design of a Game-based, Virtual Training System. In: Conference Proceedings. International Conference on Applied Human Factors and Ergonomics(AHFE-2012), July 21-25, San Francisco, CA, United States, AHFE, 2012

Lawson, G., Hermawati, S., D’Cruz, M., Cobb, S., Shalloe, S.

Human factors research methods in the design and evaluation of applied virtual environments Publication at the Dutch Journal of Ergonomics

Hermawati, S., Lawson, G.

User-centred design of virtual training for automotive industries. In Ergonomics & Human Factors Conference, April 15 -18, Cambridge, UK, 2013

Hermawati, S., Dadashi, N., Lawson, G., and Wilson, J.

Ethical issues in developing a game-based virtual training system for final assembly lines in automotive manufacturers. Award winner of the Observatory on Responsible Research and Innovation in ICT

Hermawati, S., Lawson, G., D’Cruz, M., Arlt, F., Apold, J., Andersson, L., Gink Lovgren, M. and Malmskold, L. (2015) Understanding the complex needs of automotive training at final assembly lines. Applied ergonomics, Vol: 46, Part A, Jan 2015, pp. 144 (http://www.sciencedirect.com/science/article/pii/S0003687014001367)

LANGLEY, A., LAWSON, G., HERMAWATI, S., D'CRUZ, M., APOLD, J., ARLT, F. and MURA, K., 2016. Establishing the Usability of a Virtual Training System for Assembly Operations within the Automotive Industry: Human Factors and Ergonomics In Manufacturing Human Factors and Ergonomics In Manufacturing, Vol 26, Issue 6, Nov 2016, pp. 667-679

VISTRA deliverables

VISTRA project partners

European Commission CORDIS: Virtual Simulation and Training of Assembly and Service Processes in Digital Factories

IMOSHION: Improving Occupational Safety and Health in European SMEs with the help of Simulation and Virtual Reality

Title: IMOSHION: Improving Occupational Safety and Health in European SMEs with the help of Simulation and Virtual Reality

Funder: European Commission Framework Programme 7 (SME-243481)

Total value: €2,864,556.50

Start to end date: March 2011 – February 2014

Summary:

The project IMOSHION (Improving Occupational Safety and Health in European SMEs with help of Simulation and Virtual Reality) is implemented by 10 partners from 6 European countries that have a common interest in improving working conditions in small and medium sized enterprises in the manufacturing sector. The project focuses on two aspects: On the one hand it collects existing knowledge and creates new information concerning OSH issues. On the other hand it wants to develop tools and techniques to raise awareness and improve OSH in SMEs.

Key publications:

FLOYDE, A., LAWSON, G., SHALLOE, S., EASTGATE, R. and D'CRUZ, M., 2013. The design and implementation of knowledge management systems and e-learning for improved occupational health and safety in small to medium sized enterprises: Safety Science Safety Science. 60, 69-76

IMOSHION background information

European Commission CORDIS: IMOSHION

ManuVAR: Manual work support throughout system lifecycle by exploiting virtual and augmented reality

Title: ManuVAR: Manual work support throughout system lifecycle by exploiting virtual and augmented reality

Funder: European Commission Framework Programme 7 (NMP–211548)

Total value: €9,649,244.00

Start to end date: May 2009 – April 2012

Summary:

Manual work (MW) is a central and expensive component of manufacturing, assembly, testing and maintenance services in Europe. There are many industrial sectors that rely on the knowledge and skills of their manual workers, for example, satellite assembly, maintenance of nuclear reactors, operation of complex machinery, design and manufacturing of highly customised products. In these sectors, MW constitutes the core operations and it cannot be off-shored or automated. According to Eurostat (2008), there are about 19 million people involved in the high knowledge high value MW in Europe, mainly as plant and machine assemblers and operators. Considering the entire product lifecycle (LC) from design to recycling, the number of people related to MW is even larger.

The MANUVAR objective is to provide a systematic technological and methodological system to support high knowledge high value MW throughout the product LC. It combines the best potential of the lean and agile models with the knowledge and skill management in the product LC. The ultimate goal of MANUVAR is to go 'beyond lean manufacturing' in order to:

- increase productivity and quality and reduce cost of manual work in the whole LC ('lean');

- facilitate adaptation to product customisation and changes ('agile');

- Support efficient knowledge and skill management and bi-directional data and knowledge flows through the LC ('beyond')

HFRG members:

Project partners:

- Technical Research Centre Of Finland (VTT), Finland

- Fraunhofer Institute For Factory Operation And Automation (IFF), Germany

- Netherlands Organization For Applied Scientific Research (TNO), Netherlands

- Fatronik - Tecnalia, Spain

- Institute Of Communications And Computer Systems (ICCS), Greece

- Trinity College, University Of Dublin (TCD), Ireland

- University Of Malaga (UMA), Spain

- University Of Nottingham (Unott), UK

- Tampere University Of Technology (TUT), Finland

- Thales Alenia Space Italia (TAS-I), Italy

- IPA Total Productivity (IPA TP), Netherlands

- New Strategies Of Maintenance S.L. (NEM S.L.), Spain

- Tecnatom, Spain

- Carr Communications, Ireland

- Hermia Business Development (HBD), Finland

- Association For Advancement Of Radical Behavior Analysis (AARBA), Italy

- Cards PLM Solutions, Netherlands

- Metso Minerals, Finland

Key publications:

- Liston, Paul M., Kay, Alison, Cromie, Sam, Leva, Chiara, D'cruz, Mirabelle, Patel, Harshada, Langley, Alyson, Sharples, Sarah And Aromaa, Susanna, 2012. Evaluating The Iterative Development Of Vr/Ar Human Factors Tools For Manual Work Work-A Journal Of Prevention Assessment & Rehabilitation. 41, 2208-2215

- Liston, Paul, Cromie, Sam, Leva, Maria-Chiara, Helin, Kaj And D'cruz, Mirabelle, 2010. Manuvar Training: Supporting The Implementation And Design Of Vr/Ar Quality-Improvement Tools For Manual Handling Advances In Occupational, Social, And Organizational Ergonomics. 653-663

- Krassi, Boris, D'cruz, Mirabelle And Vink, Peter, 2010. Manuvar: A Framework For Improving Manual Work Through Virtual And Augmented Reality Advances In Occupational, Social, And Organizational Ergonomics. 725-734

ManuVAR deliverables

European Commission CORDIS: ManuVAR Result In Brief

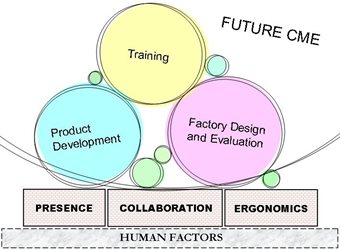

DiFac: Digital Factory for Human Oriented Production System

Title: DiFac: Digital Factory for Human Oriented Production System

Funder: European Commission Framework Programme 6 (IST-035079)

Total value: €3,617,542

Start to end date: May 2006 – Apr, 20011

Summary:

A digital factory is a persistent community where a rich virtualized environment, representing a variety of factory activities, will facilitate the sharing of factory resources, manufacturing information and knowledge and help with the simulation of collaborative design, planning, production and management among different participants and departments.

The DiFac project (EU project number FP6-IST-5-035079 http://www.difac.net/) is a framework of methods and tools which is being built upon the theoretical foundations of presence, collaboration and ergonomics. The DiFac framework will support group work in an immersive and interactive way, for concurrent product design, prototyping and manufacturing, as well as worker training. It will provide support for data analysis, visualization, advanced interaction and presence within virtual environments, ergonomics analysis, and collaborative decision-making.

HFRG members:

Project partners:

- Industrial Technology and Automation of the National Research Council of Italy ITIA-CNR, Italy

- Mathématiques S.A MASA, France

- Computer and Automation Research Institute of Hungarian Academy of Sciences SZTAKI, Hungary

- Laboratory for Manufacturing Systems and Automation of the University of Patras LMS, Greece

- Fraunhofer Institute for Manufacturing Engineering and Automation IPA-FhG, Germany

- Technology Transfer System S.R.L TTS Italy

- Ropardo S.R.L ROPARDO, Romania

- V-Fab GmbH V-FAB, Germany

- Metaio GmbH METAIO, Germany

- Prima Industrie S.p.A, Italy

- Pantelis Pashalidis & Sons S.A PPS, Greece

Key publications:

- Sacco, Marco, Redaelli, Claudia, Constantinescu, Carmen, Lawson, Glyn, D'cruz, Mirabelle And Pappas, Menelaos, 2007. Difac: Digital Factory For Human Oriented Production System Human-Computer Interaction, Pt 4, Proceedings. 4553, 1140-1149

- Lawson, Glyn And D'cruz, Mirabelle, 2011. Ergonomics Methods And The Digital Factory Digital Factory For Human-Oriented Production Systems: The Integration Of International Research Projects. 23-34

Intelligent Manufacturing Systems

European Commission CORDIS: Digital factory for human oriented Production System

Cloud Manufacturing

Title: Cloud Manufacturing

Funder: EPSRC

Summary:

UK economic prosperity increasingly depends on maintaining and further developing a resilient and sustainable manufacturing sector that is based on sophisticated technologies, relevant knowledge and manufacturing framework, that has the ability to produce a variety of products faster, better and more affordable. High labour cost economies will require an infrastructure that can quickly respond to consumer and producer requirements, that will minimise the use of materials, energy, transport and resources while maximising environmental sustainability, safety and economic competitiveness.

We address these needs with a research programme centred on the concept of ‘Cloud Manufacturing’. The programme is a radical departure from the current philosophy of manufacturing ICT – it creates a framework for manufacturing entities to participate and contribute information and support services to the consumers and the users of the products.

The role of Human Factors within the Cloud Manufacturing project is to understand the requirements for user-centred design within this new paradigm. This includes understanding effective decision support within highly distributed manufacturing supply chains, HMIs for envisioning the matching of products to cloud manufacturing services, and new models of collaboration.

Key publications:

Golightly, D., Sharples, S., Patel, H., & Ratchev, S. (2016) Manufacturing in the Cloud: A human factors perspective. International Journal of Industrial Ergonomics, 55, 12-21.

Golightly, D., Sanderson, D., Holmes, P., Ratchev, S., Sharples, S. Design requirements for effective hybrid decision making with Evolvable Assembly Systems. European Conference on Cognitive Ergonomics, 2016.

Evolvable Assembly Systems

Title: Evolvable Assembly Systems

Funder: EPSRC

Summary:

Assembly of final products in sectors such as automotive, aerospace, pharmaceutical and medical industries is a key production process in high labour cost areas such as the UK. To respond to current challenges manufacturers need to transform current capital-intensive assembly lines into smart systems that can react to external and internal changes. There is a need for a radically new approach toward development of future assembly systems able to continuously evolve in order to respond to changes in product requirements.

The research delivers a new pattern shift in adaptable and cost effective manufacture that breaks with traditional approaches and is affirmed of the following foundational research challenges:

- Product-Process System Evolution

- Data Analytics; Knowledge Modelling

- Emergence Engineering

- Open Manufacturing

The contribution of Human Factors within this project is to understand how automation and decision-support in an evolvable assembly environment can be delivered in user-centred manner to deliver high performance collaboration between humans and automation/robotics

EPSRC Evolvable Assembly Systems - Institute for Advanced Manufacturing