Monday, 23 November 2020

The University of Nottingham has secured £801,874 in funding from the Medical Research Council to accelerate development of the world's first optical fibre sensor-equipped endotracheal tube (iTraXS).

Endotracheal tubes (ETTs) are placed in the trachea (windpipe) in patients who need artificial breathing support. iTraXS aims to prevent pressure injury to the airway and to assist with monitoring vital signs.

Worldwide, approximately 120 million surgical and intensive care patients a year rely on ETTs. The tube has an inflatable, balloon-like, "cuff", which sits inside the trachea forming a gas-tight seal to prevent leaks of oxygen-rich air and maintain effective ventilation. The seal also protects the lungs from contamination by vomit or blood which can lead to ventilator-associated pneumonia (VAP). VAP occurs in 8-28 per cent of ventilated ICU patients. On average, VAP increases length of stay by six days, and mortality by up to 50 per cent. Each episode costs the NHS on average £12,000.

Incorrect cuff inflation pressure causes two main problems. If pressure is too low, it can risk fluid getting past the cuff and causing VAP. Conversely, if pressure is too high it can cause pressure injury in the trachea.

Pressure injuries range from moderate to severe sore throat, voice change or cough in half of all patients after surgery (0.5 million a year in the UK), to permanent scarring and narrowing of the windpipe tissue (post intubation tracheal stenosis - PITS), which occurs in around 2000 patients annually. PITS is a disabling condition, with patients living “from breath to breath” and reporting long-term adverse impact on quality of life and multiple medical interventions.

At present there is no medical device on the market to accurately and safely measure and monitor the contact pressure of the inflated cuff and the blood flow in the tracheal lining (mucosa).

Current best practice recommends maintaining a fixed pressure in all patients. However, iTraXS enables personalised care by allowing clinical staff to find the correct pressure for each patient, balancing a good seal versus tissue pressure and blood flow.

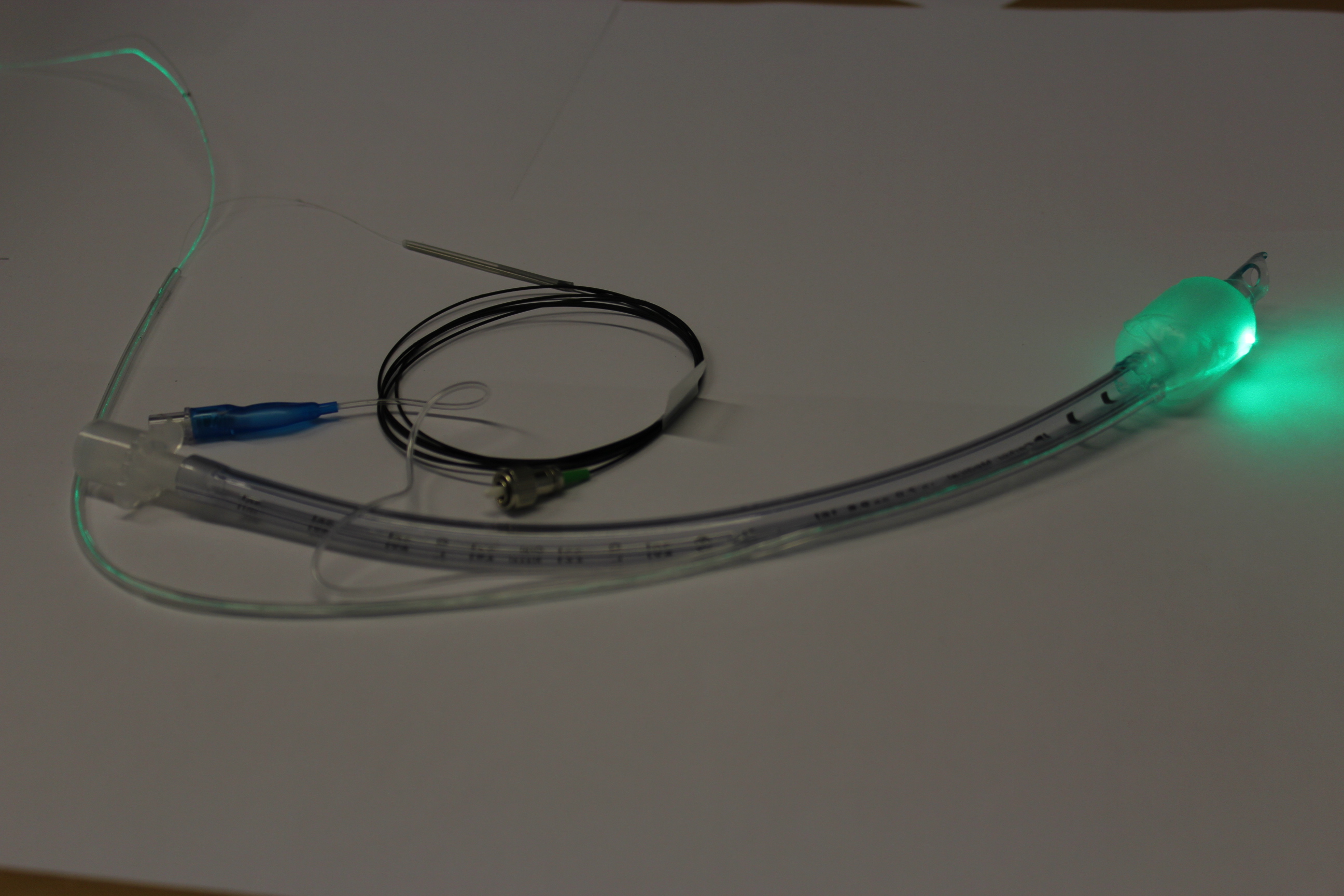

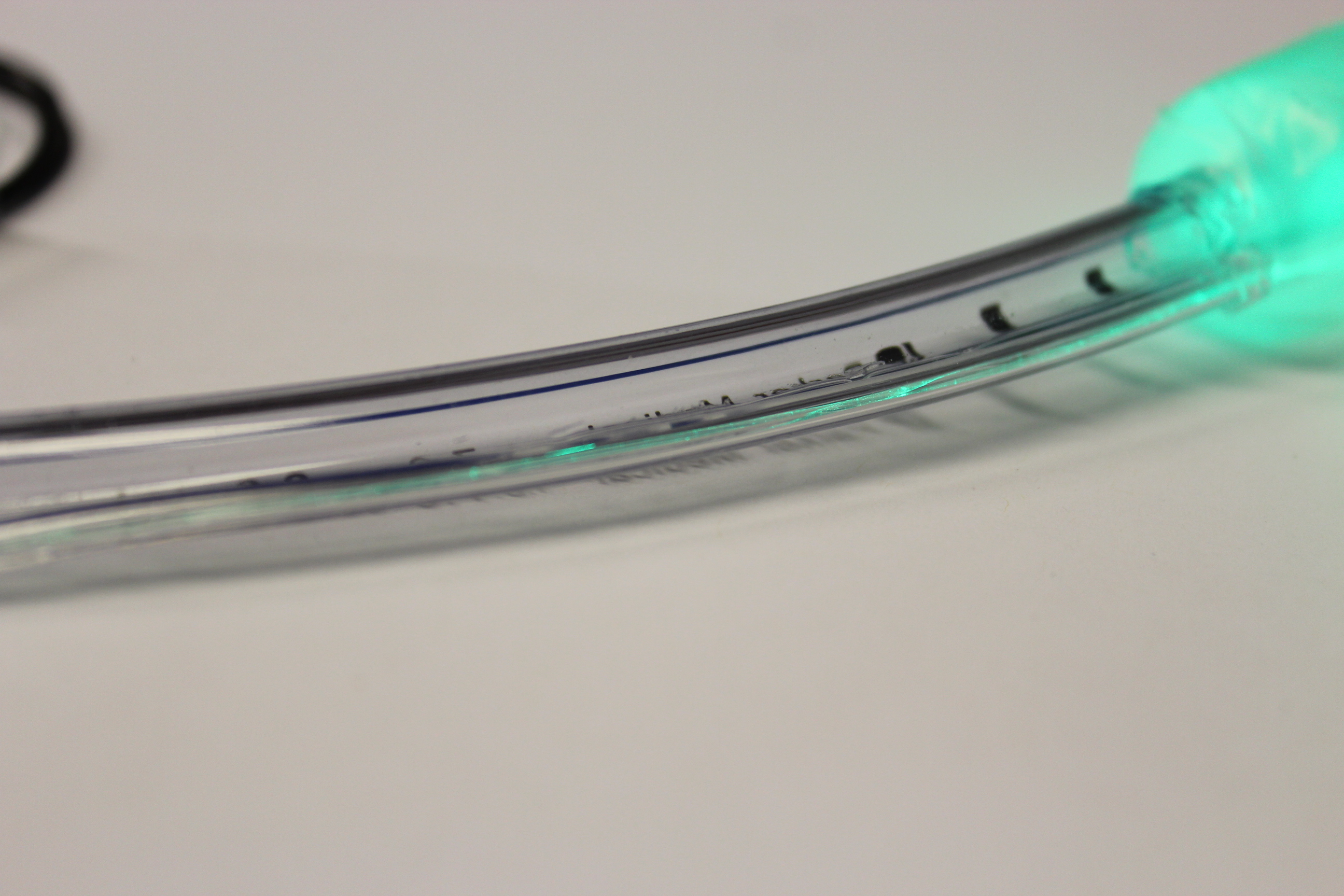

The University of Nottingham-developed endotracheal tube embedded with optical fibre sensors

The University of Nottingham-developed endotracheal tube embedded with optical fibre sensors

iTraXS uses thin, flexible, optical fibre sensors incorporated into a standard disposable ETT, which is linked to an optoelectronic monitoring and display unit.

The device successfully monitors both the contact pressure and the blood supply at the cuff-trachea interface (the point where the cuff touches the windpipe lining) to ensure a good gas seal while avoiding windpipe injury. The concept has won widespread support including an award from the Association of Anaesthetists of Great Britain and Ireland in 2018.

iTraXS measurements could also aid ETT placement and vital sign monitoring (oxygen saturation, heart rate, pulse volume, temperature) in pre-hospital conditions. This could replace multiple devices such as finger clip oxygen monitors which can be inconvenient on the battlefield or in an ambulance, or be inaccurate due to limb loss or low blood pressure, for instance.

“iTraXS demonstrates the potential of emerging optical sensor technology to enable real-time monitoring inside patients, providing previously unavailable data to aid clinical decision making and improving the surgical experience of patients worldwide.”

Thanks to the new MRC funding, the researchers aim to develop regulatory compliant software and hardware and expand the number and functionality of sensors built into iTraXS. At the end of the current project the device will be ready for clinical trials and could be CE-marked and brought to market within three years.

Professor Morgan thinks the scope of iTraXS could be broadened to meet other healthcare needs with a range of different smart tubes. “Optical fibre sensing is a versatile platform technology that can measure a range of physical and biochemical parameters and could equally be applied to any internal catheter. With appropriate modification, such as a functional coating, the sensing capability can be significantly extended to monitor, for example, biofilm formation (bacterial growth) which is a major cause of infection.”

Optical fibre sensing technology at work in the 'smart' breathing tube

Optical fibre sensing technology at work in the 'smart' breathing tube

ITraXS has been developed in partnership with P3 Medical Ltd, a Bristol-based manufacturer of endotracheal tubes and Nottingham University Hospitals NHS Trust (NUH).

Dr David Hewson, Consultant Anaesthetist at NUH and one of those involved in delivering the research, said, "This substantial award from the Medical Research Council means this innovative smart medical device is one step closer to being used in patients. This project is about new ways to monitor the health of patients in ICU and reduce their risk of pneumonia and damage to their trachea while on life support ventilators.

“If we are able to do that we could reduce the length of time patients need to stay on intensive care and improve their recovery from critical illness. The technology used in this project could be translated into many other medical situations allowing doctors to accurately monitor patients using 21st century smart devices."

Andrew Norris, Honorary (Clinical) Associate Professor at the University of Nottingham and Consultant in Anaesthesia said, "Tracheal intubation is a vital part of critical care, but the tubes do cause harm and have never been capable of any monitoring function. iTraXS, the world's first smart ET tube, entirely developed in Nottingham, has great potential to reduce harm and provide vital data on the condition of patients. A similar approach could revolutionise the many “dumb” invasive devices currently used in surgery and critical care.”

Story credits

More information is available from Professor Steve Morgan, Co-Director (Research lead) at the Centre for Healthcare Technologies, on steve.morgan@nottingham.ac.uk or Emma Lowry Media Relations Manager on emma.lowry@nottingham.ac.uk

Notes to editors:

About the University of Nottingham

Ranked 97 in the world and 17th in the UK by the QS World University Rankings, the University of Nottingham is a founding member of Russell Group of research-intensive universities. Studying at the University of Nottingham is a life-changing experience, and we pride ourselves on unlocking the potential of our students. We have a pioneering spirit, expressed in the vision of our founder Sir Jesse Boot, which has seen us lead the way in establishing campuses in China and Malaysia - part of a globally connected network of education, research and industrial engagement.

Nottingham was crowned Sports University of the Year by The Times and Sunday Times Good University Guide 2024 – the third time it has been given the honour since 2018 – and by the Daily Mail University Guide 2024.

The university is among the best universities in the UK for the strength of our research, positioned seventh for research power in the UK according to REF 2021. The birthplace of discoveries such as MRI and ibuprofen, our innovations transform lives and tackle global problems such as sustainable food supplies, ending modern slavery, developing greener transport, and reducing reliance on fossil fuels.

The university is a major employer and industry partner - locally and globally - and our graduates are the third most targeted by the UK's top employers, according to The Graduate Market in 2024 report by High Fliers Research.

We lead the Universities for Nottingham initiative, in partnership with Nottingham Trent University, a pioneering collaboration between the city’s two world-class institutions to improve levels of prosperity, opportunity, sustainability, health and wellbeing for residents in the city and region we are proud to call home.

More news…