Kah Leng

Next Generation Multi-Layered Thermal Barrier Coatings for CMAS Resistance

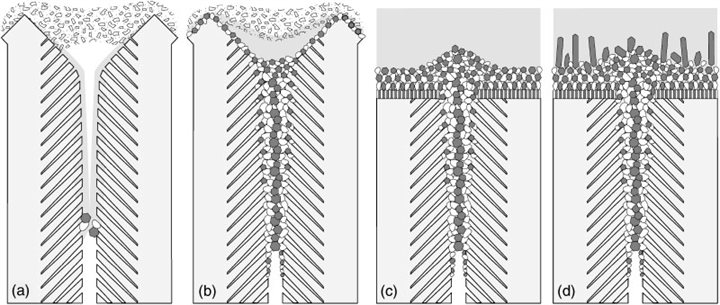

The schematic represents a column structure of TBCs. Molten CMAS infiltrates TBCs via these structures or pores. The diagram labelled as (a) showed that the molten CMAS filled up the column tip of TBCs and initiated reaction with TBCs. The diagram labelled as (b) showed that the channel filled up with reacted products which stop further infiltration of molten CMAS in TBCs.

PhD project developed by Kah L. Leng on the development of a new composition of thermal barrier coatings (TBCs) through liquid feedstock based on suspension or solution precursor thermal spray for better durability beyond 1200°C.

Calcia-Magnesia-Alumina-Silica (CaO-MgO-Al2O3-SiO2), also referred to as CMAS possesses the most significant threat from preventing the increment of the turbine entry temperature (TET) in aerospace industries to achieve a higher engine efficiency. It ingested into the engine together with air intakes, causing erosion damage on low surface temperature engine components and CMAS attack on high surface temperature engine components. CMAS can be in the form of volcanic ashes, debris, fly ashes and sand. However, the composition of CMAS varies in locations, which led to a melting temperature of approximately 1200°C. As CMAS touches the high surface temperature engine components, CMAS turns into a molten state and rapidly infiltrates into TBCs. Consequently, dissolution of TBCs occur and eventually, spallation of TBCs from the engine component.

This project aims to develop a new composition of TBCs, which specifically reacting with CMAS to form a sealing layer to prevent further infiltration through the use of thermal spraying techniques, solution precursor high-velocity oxy-fuel and suspension HVOF. For a better understanding of the new composition, a single layer TBC will be initially developed to determine the physical properties of the coating, such as porosities, hardness and thermal conductivities. The durability of the new composition will be interested and tested through the use of thermal cyclic rig and burner rig testing.