Fibre laser cladding for power generation

CME team is developing laser based cladding from powder and wire feedstock for high temperature corrosion and wear applications. The laser used for our research is a 2 kW IPG photonics fibre laser. Our laser setup is equipped to clad flat plates and boiler tubes through a combination of x-y traverse unit and various rotational axes. We are also developing composite coatings using a combination of Cr3C2 powder and APMT wire feedstock to produce a laser clad with excellent high temperature corrosion and erosion properties.

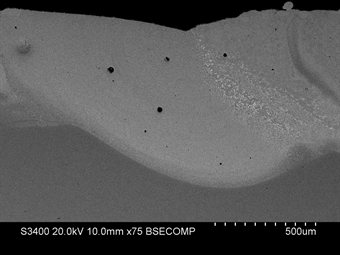

Laser cladding of Ni50Cr onto power plant steel

Laser cladding of Ni50Cr onto power plant steel

Laser cladding of nanosteel onto power plant steel