Research

Our research group currently consists of postdoctoral researchers, PhD students and masters students. Our group is very dynamic as we often work alongside visiting academics, summer students and international researchers.

We work with a range of partners with funding from:

- UK Research Councils

- The European Commission

- EU and Multinational Industries

The group is supervised by Prof. Steve Howdle.

The groups interests lie in the use of supercritical carbon dioxide (scCO2) as a new solvent for polymer synthesis and materials processing. This is an exciting area that has led to collaboration with many other disciplines; from chemical engineers in the USA and Portugal; to industrial polymer producers throughout Europe and beyond; through to laser physicists in Moscow.

A major part of the group's research is directed towards multidisciplinary collaborations on clean synthesis of new polymers and new polymeric structures using supercritical fluids.

Examples of Current Research Projects

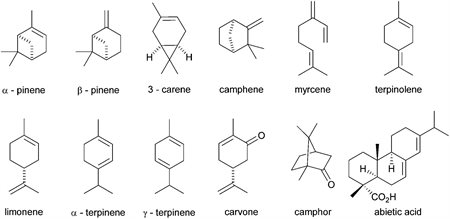

The group is currently working on a joint project with the Stockman group synthesising and polymerising terpene monomers.

300 million tonnes of polymers are produced annually, mainly derived from fossil fuels, with <5% being sourced from renewable sources. The rapid depletion of these fossil fuels, along with their damaging contribution to the environment, means the need to source materials from renewable sources has greatly increased. Terpenes are abundant, inexpensive and are obtained from a renewable feedstock. Despite containing alkene moieties terpenes do not readily undergo radical polymerisation. Therefore the research carried out in our group focusses on the synthesis and polymerisation of new terpene derived monomers utilising radical polymerisation techniques, ring opening polymerisation and condensation polymerisation for a number of applications.

Dispersion polymerisation

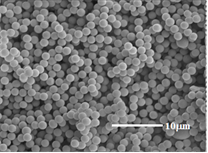

Dispersion polymerisation is used by the group to produce particles with highly controlled morphologies.

Large molecules such as polymers are often insoluble in scCO2. Thus, the development of stabilisers to aid the dispersion of the growing polymer chain in the supercritical phase is a key area of research within the group.

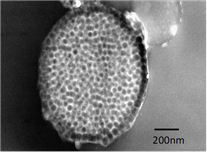

The key advantage with this process is that high molecular weight polymers are obtained as clean, dry, solvent-free fine powders. Using RAFT control, we have recently created unusual nanostructured polymeric microparticles using dispersion polymerisation in CO2.

SEM image of polymer particles produced using a stabiliser

SEM image of individual polymer particles

Internal morphology of block copolymer particles

The group has recently purchased a rheometer with high pressure capabilities. This can be used to study the mechanical properties of polymers as they are processed/synthesised in scCO2. As scCO2 is known to greatly decrease the viscoisty of some polymers, this is a valuable tool for material characterisation.

Our capabilities

We have experience with a number of analytical and synthetic techniques,

- High pressure rheology

- Thermal analysis

- Controlled polymerisation

- SAXS (including high pressure)

- Supercritical fluid extraction

- Foaming

If you think we could work together, please contact us through the channels listed below.

If you have any questions regarding

- Our research

- Resources

- PhD & placement opportunities

Do not hesitate to use the contact details below.