Advanced Manufacturing Processes

Machining and Condition Monitoring (MCM) Team has a good capability on advanced manufacturing technology such as conventional machining, waterjet milling/cutting, pulsed laser ablation, ultrasonic polishing, as well as in depth materials properties characterisation (SEM, XRD, EBSD, TEM, Raman Spectroscopy, Micromechanics test) after machining.

The relevant materials are such as Superalloys, Composites, Biomaterials, Thermal Barrier Coatings etc. Innovative monitoring of manufacturing processes using a wide range of sensing solutions (force cells, accelerometers, acoustic emission, laser, strain gauges, PVDF, high speed imaging systems, etc) have also been developed.

Contacts

Academics

Researchers

Postgraduates

Research and Developement List

Here you can find information about our projects.

Surface Integrity Analysis of Machined Parts

Surface Integrity refers to the alteration of machined surfaces compared to those of the bulk material, in terms of metallurgical, mechanical and chemical properties.

Exceeding particular surface anomalies limits can lead to a decline in service performance, this can be from failure modes such as fatigue.

Surface inspections are performed to ensure the absence of defects (such as cracking, high lapping or plucking) on machined surfaces and to provide “damage free” surfaces for improved fatigue performance, which is of the highest priority for aerospace components.

Advanced Machining Capability for Aerospace and "Difficult-to-cut" Materials

Machining of complex and/or light-weight aerospace components made of Ni/Ti superalloys require the use of innovative machining techniques to address key challenges such as surface integrity, dynamic behaviour, and accelerated tool wear.

In addition to developing innovative and patented tooling technologies for machining complex profiles in aerospace alloys, we have expertise in process parameter selection based on surface integrity analysis, part and machine tool dynamics.

Extensive experience also exists in evaluation of machining cutting fluids.

Abrasibe Waterjet Machining

The MCM research team has extensive experience in performing experimental and analytical/finite element modelling of Abrasive Waterjet Machining (e.g. through cutting, milling, cleaning) of a wide range of materials for the manufacture of high value-added components for aerospace, medical and tooling industries.

Challenges in bone cutting and the novel solutions

Bone cutting is an important procedure in most surgery operations, surface/tool damages, high cutting temperature/force need to be avoided. Studying and modelling bone cutting chip formation mechanism is important to design tools and optimise the surgery process.

MCM have investigated and modelled the chip formation mechanism in bone cutting process while a wavelet based process monitoring process was proposed with AE sensory measure for monitoring bone cutting process and support the understanding of the cutting phenomena on this unique material. We also proposed a novel design of a milling cutter which includes on the back of main cutting edge a succession of micro-cutting edges arranged on an Archimedes spiral that allows the limitation of surface damage. The tool benefits with high cutting efficiency, smooth surface, low cutting force and temperature.

Pulsed Laser Ablation for micromachining applications has gained an enormous following in recent years due to their ability to machine virtually any material, producing features with resolution on the orders of micrometres while simultaneously causing small thermal and surface damage to the workpiece.

Various projects related to the use of PLA for micromachining of hard-to-cut materials (i.e. superalloys, ceramics), as well as modelling to achieve in-process control of the removal process, are currently being investigated at the UTC.

Coating Technology represents a key area in the aerospace industry, demanding constant improvements to keep pace with recent trends in modern aeroengine design. In order to achieve a higher control on coating specific properties to match any particular application, it is essential to gain a fundamental understanding on behaviour of the material and its response to external stimuli.

Machining of Ceramic Matrix Composites (CMCs)

Frames from the high speed imaging system showing the cutting mechanism for different fibre orientation.

Ceramic Matrix Composites (CMCs) have been an important research field within the aerospace industry in these last years. The anisotropic, heterogeneous, brittle and hard nature of these materials challenges the machining process in terms of surface characterisation and tool design.

Different projects where the fundamentals of cutting and surface characterisation are studied followed with the development of novel cutting tools.

Customised micro-patterning of diamond structures for precision tooling application

Micro-pattern Polycrystalline Diamond (PCD) tools for grinding and dressing applications.

The limitations of conventional machining methods with undefined cutting edges on the prediction of the impressions left on the work surface are directly associated to the inherent stochastic nature of the abrasive particles with regard to their size and protrusion, shape, location and spacing.

An innovative approach of engineered (super)abrasive tools based on the generation of controlled-shape micro-feature arrangements on PCD and CVD diamond structures with pulse laser ablation has been taken to overcome the randomness associated with the material removal process. This concept opens the door to the customisation of precision tooling for specific applications (drilling, dressing, grinding, etc.) and difficult-to-machine workpiece materials.

APS Thermal Barrier Coating

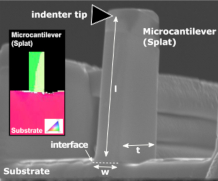

Single Splat of APS TBC

Micro-pillar for adhesion strength testing

Coating Technology represents a key area in the aerospace industry, demanding constant improvements to keep pace with recent trends in modern aeroengine design. In order to achieve a higher control on coating specific properties to match any particular application, it is essential to gain a fundamental understanding on behaviour of the material and its response to external stimuli.

The UTC has been involved in a number of projects to perform advanced characterization of Thermal Barrier Coatings (routinely used in aeroengines), as well as currently developing new technology to allow in-situ repair of delaminated coatings from within the engine.

Surface Integrity Conscious High-Performance Hybrid Machining for Safety-Critical Superalloy Aeroengine Parts (STIMULANT)

STIMULANT aims to develop and demonstrate “surface integrity conscious” hybridisation of machining processes for safety-critical aero engine parts that is able to deliver a step-change in Material Removal Rates (MRR) and reduction in production costs. STIMULANT will take key knowledge at different levels of maturity that exists within Consortium, and progress it, via Standard Features (StdFs) methodology, to the demonstration on “engine-like” safety critical parts.

Tell me more

Sensor Enabled Systems for Precision Cutting (SENSYCUT)

Machining is one of the most used processes for producing precision parts used in aerospace and automotive industries. The demand for high performance and quality assured parts requires high precision, often over a large scale resulting in increased manufacturing costs. It has become a rule of thumb that precise machines with stiff structures and large foot prints are required for machining precision parts. As a consequence, machining costs grow exponentially as the precision increases. This has resulted in the development of expensive and non-value adding off-line verification and error compensation methods. However, these methods do not take the impact of cutting tool/workpiece geometry, cutting forces and time variable errors into account. The uptake of additive manufacturing has also resulted in generation of optimised parts often with complex geometries and thin and high walls which require finish machining with long slender tools. In these scenarios, cutting forces can bend the tool and the workpiece resulting in geometrical inaccuracies. Fluctuating cutting forces result in chatter leading to damaged surface integrity and short tool life.

Using new sensors, advanced signal processing and intelligent control systems can provide the ability to detect geometrical and surface anomalies when machining, and provide data to generate strategies to prevent costly mistakes and poor quality. However, off-the-shelf sensors and data transmission devices are not necessarily suitable for monitoring and controlling machining processes. Existing high precision sensors are either too large or too expensive making them only useful for laboratory applications. Conventional statistical and process control methods cannot cope with high data sampling rates required in machining.

The proposed research will realise low-cost sensors with nano scale resolution specific to machining, tools and intelligent control methods for precision machining of large parts by detecting and preventing anomalies during machining to ensure high precision part manufacture and prevent scrap production.

Tell me more