Biaxial Machine for Fabric and Foils

Designing, developing and implementing a modular self-supporting structural-construction system comprimised of linked ETFE foril encapsulated panels

The testing equipment has been founded by InnovateUK within the activity of the Knowledge Transfer Partnership - KTP9213 (2013-2015) between the University of Nottingham and Holscot Fluoroplastics Limited.

Key contact:

Aim

The task aimed to investigate the potential of a Raspberry-Pi micro-controller in the development of cost effective test equipment for the investigation of the mechanical performance of architectural coated fabrics and foils.

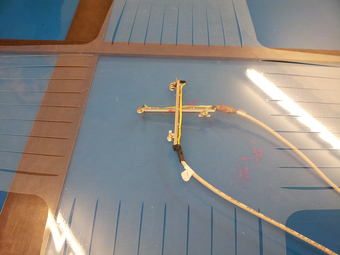

The testing device is composed by a data logger, able to record several channels simultaneously, and a metal rig 130cmx130cm able to test a cruciform sample 90cmx90cm with a central area of 30cmx30cm and arms 30cm long. Each side of the ETFE sample, which is previously folded over a cylindrical bar which prevents any slippage, is held by an aluminum keder rail 50cm wide. The load is applied manually through a threaded bar, however, the next development of the biaxial machine aims to include actuators directly controlled by the Raspberry-Pi micro-controller.

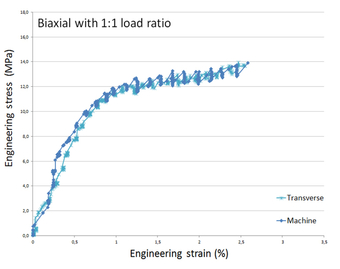

The force is measured by means of up to four S type load cells (Phidget CZL301) designed for a maximum force of 5kN. The elongation of the material is measured through up to three linear potentiometers (Alps RSA0N11S9002) with a maximum stroke of 100 mm. The data of force and elongation are recorded simultaneously and are then used to develop the stress-strain response curves (or surfaces) used for the investigation of the mechanical performance of the material. In addition, the data logger has four channels for the measurement of temperature and humidity and two sensors for the measure of pressure (0-5 Psi).

Publications

P. BECCARELLI, 2015. Biaxial Testing for Fabrics and Foils: Optimizing Devices and Procedures Springer

BECCARELLI P., MARTIN B., LAU B., CHILTON J., BONARDI S. and MAFFEI R., 2015. Single-board microcontrollers applied to biaxial tests for architectural membranes In: International IASS Symposium 2015, 17-20 August, Amsterdam, Netherlands.

BECCARELLI P., COLASANTE G., NOVATI G., STIMPFLE B. and ZANELLI A., 2013. Strain-controlled biaxial tests of coatedfabric membranes In: Tensinet Symposium 2013 [RE]THINKING Lightweight Structures 8 -10 May 2013, Mimar Sinan Fine-Art University, Istanbul. 53-65

BECCARELLI, P., BRIDGENS, B.N., GALLIOT, C., GOSLING, P.D., STIMPFLE, B. and ZANELLI, A., 2011. Round-robin biaxial tensile testing of architectural coated fabrics In: Proceedings of the International Symposia IABSE-IASS 2011:Taller, Longer, Lighter, 20-23 September, London, UK.

Datalogger Maco Technology Raspberry PI

Biaxial test 1-1 ratio behaviour strain stress graph

Control tools for fabrics

Cruciform Sample ETFE biaxial test Maco Technology