Facilities at the Centre for Additive Manufacturing

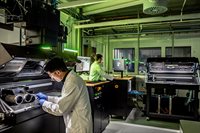

CfAM’s laboratories host a globally unique portfolio of developmental and commercially available additive manufacturing (AM) systems. This is supported by a state-of-the-art suite of analytical devices in a dedicated materials characterisation laboratory. Together, our laboratories form a vital tool for establishing new avenues of academic and industrially focused research.

Among our large portfolio of research and commercially deployed AM systems, CfAM’s main laboratory in the Advanced Manufacturing Building on Jubilee Campus boasts specialist and bespoke systems that are not available elsewhere. These include experimental multimaterial 3D inkjetting systems, ranging from small scale exploratory research platforms to large scale systems, such as the PiXDRO Toucan and Notion jetting systems, high-temperature liquid metal jetting systems (MetalJet) and custom built multimaterial high-resolution AM systems. We are also proud to have recently installed the Aconity metallic powder bed fusion system, which is an open architecture system permitting the processing of multiple metals in a single powder bed process.

This is complemented by our clean room facility (supported by the Wolfson Foundation) which provides a setting in which processes are shielded from environmental pollutants and light sources. This environment considerably widens the palette of materials for 3D inkjet and extrusion printing platforms and is used primarily for pharmaceutical, biological, and electronics-oriented research. It is equipped with a comprehensive suite of 3D inkjetting and analysis equipment, alongside pharmaceutically focused material extrusion systems.

Centre for Additive Manufacturing laboratory virtual tour

Additive Biofabrication laboratory

Working on the development of the Additive biofabrication research, Prof Ricky Wildman and Prof Felicity Rose have recently opened a dedicated 3D bioprinting laboratory within the Nottingham Biodiscovery Institute, hosting state-of-art 3D printing equipment for biological applications. These include extrusion 3D bioprinter, stereolithography and projection micro-stereolithography systems, multiphoton lithography 3D printer and dedicated mammalian cell culture areas.

The Additive Biofabrication Laboratory located within the Biodiscovery Institute is a joint venture between the School of Pharmacy and the Faculty of Engineering at the University of Nottingham. Additive biofabrication is the use of 3D printing technologies to create structures that can direct the behaviour of biological systems. This facility is unrivalled in the UK in its consolidation of the latest technologies and boasts a plethora of bioprinting equipment, including a unique portfolio of the latest light-based biofabrication technologies for high-resolution AM for healthcare applications, all of which are housed within a dedicated cell culture suite where live biological materials can be used. Technologies available span from small scale exploratory systems to develop new materials to cutting edge commercial equipment and bespoke systems built in-house. They include multiphoton lithography/ two-photon polymerisation (MPL/2PP), projection microstereolithography (pµSLA) and computed axial lithography/volumetric additive manufacturing (CAL/ VAM). With these, cell scale (10s microns) to sub-cell scale (<1 micron) resolutions can be achieved at the high fabrication rates needed for live cell printing. By housing this equipment within biological safety cabinets, cell-laden bioprints can be manufactured in a sterile environment in a clinically relevant manner

National Biodiscovery Institute biofabrication laboratory virtual tour

Additive Manufacturing laboratory in Clinical Engineering

In 2022, we established a new AM laboratory at Queens Medical Centre (QMC), in a joint venture with the Clinical Engineering department at Nottingham University Hospitals NHS Trust (NUH). The lab, which includes HP Multijet Fusion 580, Ultimaker S7, and Formlabs Form3B systems, provides a central facility for NUH staff who would like to explore the use of AM in clinical applications. This venture is designed to aid translation of research from CfAM and the wider AM community into hospitals, identifying current opportunities and future research needs. For further information, please contact Prof Ruth Goodridge.

Centre for Additive Manufacturing laboratory cutting-edge equipment

Multi-material Laser Powder Bed Fusion (LPBF) system – AconityMID+

The AconityMIDI+ is an open multi-laser mLPBF system for the production of metal parts. This custom made state of the art system benefits from 3 lasers ranging from 400w to 1Kw with the addition of an Aerosint dual material recoater, InfraTec VarioCAM thermal imaging camera, dual Kleiber pyrometers, 500°c heated substrate and an exchangeable process chambers including additional axis.

The open multi laser configuration enables total control of each laser individually, including multiple speeds and powers within a single vector. This total control, coupled with weld pool monitoring via the thermal imaging camera and pyrometers, gives the ability to manipulate and vary the microstructure within a part.

This manipulation can be applied to 2 materials within the same part when using the Aerosint dual material recoater. With the additional process chamber, a parallel setup can be prepared to minimise downtime between builds. This additional chamber also benefits from an extra axis which opens up the opportunities for future binder jetting and mLPBF research.

Multimaterial 3D Inkjetting system – PiXDRO Toucan

The PiXDRO Toucan system is a custom-built £1M inkjet machine constructed for the CfAM by the Dutch inkjet specialist Roth and Rau. The bespoke system has six piezo-electric heads permitting the jetting of six distinct materials within the same build process.

The machine is equipped with a 12 W/cm2 UV curing unit with a wavelength of 395nm, and a 1 KW infrared lamp, with a maximum filament temperature of 1500°C, for curing heat/photo-sensitive polymers and conductive materials. The large build volume is another added advantage of the Toucan system over other conventional inkjet systems available on the market.

Current projects at CfAM on this system are primarily focused on inkjetting multiple materials to produce multi-functional 3D components for electrical and electronics, pharmaceutical and biological applications.

Molten Metal Jetting 3D printing

The MetalJet system is a unique bespoke drop-on-demand 3D printing platform based on the Océ MetalJet technology. This technology enables precision jetting of molten droplets of conductive materials with a melting point up to 2,000°C.

The MetalJet system enables the jetting of liquid metal droplets onto a movable substrate to produce 3D parts from a desired stack of 2D digital patterns. Upon solidification, each layer of jetted droplets acts as a new substrate where new droplets can be dispensed to create the subsequent layer. As the process repeats, complex 3D geometries made in single or multiple semiconducting/metallic materials can be printed.

Multiphoton lithography systems

Multiphoton lithography is an advanced additive manufacturing technique capable of fabricating arbitrary 3D micro/nano structures without a mask, with resolution of around 100 nm, based on multiphoton absorption-induced polymerisation.

There are two systems available at CfAM. The commercial Nanoscribe system can fabricate in an area up to 100 x 100 mm2 with a speed up to 10 mm/s. The home-built system has extended capabilities. By combining with optical tweezers, micro/nano-sized objects can be drawn into the vat of material and encased within a matrix or attached to a surface, thus functionalise a surface or a material.

By coupling with stimulated emission and depletion (STED), it is possible to control the fabrication of 3D nano-composites precisely through the selective polymerisation or photo-reduction on demand, thus establishing a new route for metamaterial fabrication.

Commercially deployed and experimental AM systems

The Centre for Additive Manufacturing has also a range of commercially deployed and experimental additive manufacture systems, such as:

- Aconity Midi + Laser Powder Bed Fusion

- Areosint Dual metal recoater - Multi-material Powder Disposition

- Renishaw 400 SLM

- Renishaw 125 SLM

- Realizer SLM 50

- Single Head MetalJet System (Océ Technology)

- Multi Head MetalJet System

- EoS Formiga P100 (x2)

- Stratasys Connex 260

- Ultimaker S5/2+/ 2go

- Form labs 1/2/3+

- Anycubic Mono X (x2)

- Intamsys Funmat High Temp

- Integrity bespoke Binder-jet System

- FujiFilm Dimatix DMP2831 (x3)

- Suss Pixdro LP50 research Inkjet Printer (x4)

- Suss Pixdro Toucan (bespoke 6 head)

- BMF NanoArch S130 (PµSL)

- Nanoscribe Photonic Professional GT+ (2PP)

- Computed Axial Lithography System (CAL)

- Inhouse built Micro SLA systems

- Various Microfluidics Systems

Analytic machinery and research equipment

The Centre for Additive Manufacturing labs boasts an impressive array of analytic machinery and research equipment to support research:

- Perkin Elmer Thermal imaging Suit:

*DSC-8500

*DMA-8000

*TGA-4000

*FT-IR

- Clarus 680-Gas Chromatography-Mass Spectrometry System

- Krűss Drop Shape Analyser- DSA-100

- Malvern Kinexus Pro Rheometer

- Malvern Mastersizer 3000 – Particle Size Analyser

- Freeman FT4 Powder Rheometer

- Buehler Wilson VH3100 Hardness Tester

- Hamilton Microlab Star Liquid Handler

- Agilent HPLC 1260 Infinity Liquid Chromatography

- Hitachi TM3030 Desktop SEM with cold stage & EDX

- Agar splutter Coater

- Nikon Optical Microscope.