Research Challenge 1: Determination of the interface/interphase evolution at microscale

Research Challenge co-leads: Professor Clive Roberts and Professor Richard Hague

Aim: To understand, through precision experiments, the spatio-temporal interface/interphase evolution between successively deposited droplets or/voxels of multimaterials at the microscale.

To enable controlled next-generation multifunctional Additive Manufacturing at the macroscale, the two primary challenges are functional anisotropy and agglomeration of highly dissimilar materials.

To overcome these, we have developed methodologies for ex-situ materials analysis capable of delivering complete 3D characterisation of samples with chemical specificity and high resolution at the micro/nano scale, which enables us to understand how individual droplets/voxels of multiple materials temporally coalesce or interact with neighbouring materials to form continuous structures.

These methodologies employ a suite of core techniques that span a wide range of analytical spot sizes (spatial resolution) and chemical specificity, such as focused ion-beam for scanning/transmission electron microscopy (FIB-SEM), time-of-flight secondary ion mass spectrometry (ToF-SIMS), Raman spectroscopy, X-ray photoelectron spectroscopy (XPS) and atomic force microscopy (AFM). A recently acquired 3D orbiSIMS instrument will also be explored to expand the analysis of complex materials.

3D imaging mass spectrometry (3D ToF/orbi SIMS) and machine learning to analyse materials interface at droplet/voxel level.

Many of these techniques are accessed at the University of Nottingham Nanoscale and Microscale Research Centre.

RC1 is therefore key to this Programme Grant, with the application of established methodologies, as well as the constant development of new ones to answer a variety of scientific questions across the other RCs, to ultimately enable the prediction of macro-level performance (RCs 3 & 4) and to validate, predict and optimise precise deposition strategies (RC 2) for the manufacture of multifunctional devices by the three process families of interest (Material Jetting, MetalJet and 2 Photon Polymerisation).

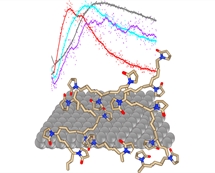

Chemical analysis of interface between silver and polymer stabiliser in inkjet printed nanoparticles.

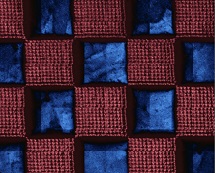

Tof-SIMS analysis of 3D printed heterogeneous specimens.

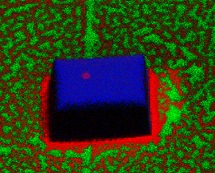

Large area chemical mapping of MetalJet pattern.

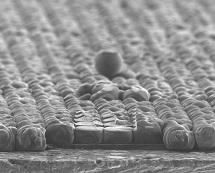

Electron microscopy of a single layer of MetalJet droplets with interface of a pair exposed by FIB.

.FIB-SEM to assess the interface between MetalJet droplets

Electron microscopy of a cross section of a hybrid organic-inorganic inductor made via multi-material 3D inkjet printing