Research Challenge 2: Multifunctional AM Computational Modelling Framework

Research Challenge co-leads: Prof Ian Ashcroft and Prof James Sprittles

Aim: To accurately model and simulate multimaterial AL; from constituent materials to multifunctional components.

The essence of AM processes in this Programme is the targeted deposition and solidification of small, carefully controlled amounts of fluid (microdrops or voxels) to build complex structures. Given the complexity of the processes, particularly when multiple materials are present, and the extremely small time and length scales involved, developing and optimising these processes requires accurate quantitative models of both the manufacturing process and the functional performance of the manufactured parts in-service.

The models and computational tools that we are developing are based on the theoretical understanding of the physical and chemical processes involved in AM (fluid dynamics, heat transport, photochemistry, light absorption, polymer rheology, solidification and microstructure formation, dynamic wetting, solid mechanics, etc.)

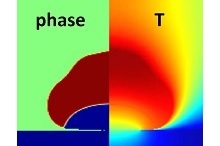

Simplified model of a hot liquid metal drop travelling from the printhead to the substrate, with streamlines of argon gas flow and colours showing the temperature

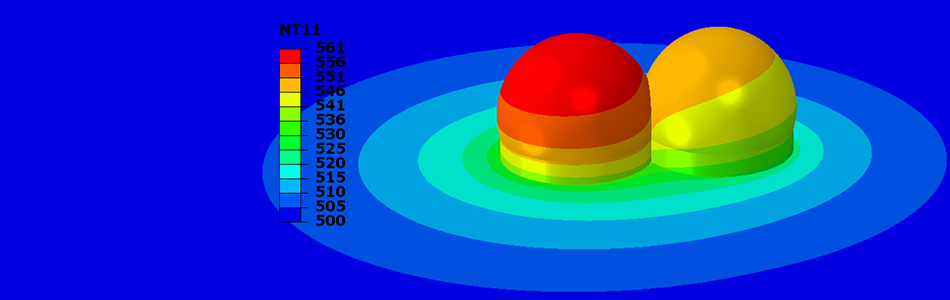

Through close collaboration with the experimentalists, our ongoing modelling efforts are yielding applicable results, e.g. reducing the ‘sagging’ of inkjet printed polymers. We are also engaged in modelling two-photon polymerisation and various aspects of MetalJet (droplet cooling in flight and spreading on the surface, solidification, including microstructure formation, and the solid mechanics of solidified droplets).

Multi-droplet impact on a solid surface (underlying mesh evolution shown)

Volume of fluid and temperature distribution of metaljet droplet impact on a solid surface