Research Challenge 4: Controlled co-deposition of multimaterials

Research Challenge co-leads: Chris Tuck and Mark Fromhold.

AIM: To investigate and demonstrate strategies for the macroscale co-deposition of functional and structural materials via piezo driven jetting, high temperature metal-jetting and functionalised multi-photon techniques.

Our goal is to achieve the co-deposition of disparate micro-droplet materials at the macroscale with controlled interactions at the interface, structural integrity and the functional performance required for their applications ranging from optoelectronic devices to pharma/healthcare uses.

By working closely with our industrial partners and building on the micro/nano-scale understanding of materials investigated in RC1, and the macroscale single material functionality gained in RC3 we can develop multifunctional 3D architectures. Multifunctional AM is informed by and feeds into the mathematical and computational frameworks developed in RC2.

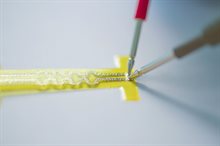

Microchannels that mimic vasculature fabricated using multi material inkjet printing

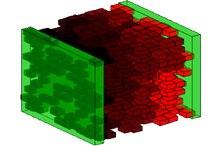

We have achieved and optimised co-deposition of multimaterials and have developed process strategies for manufacturing various structures, such as heterostructures based on low dimensional materials, and materials enabling controlled drug release, etc.

To harness the full potential of AM for the co-deposition of functional materials, in RC4 we are further developing manufacturing and post deposition processes to achieve/control functional anisotropy and are expanding the range of materials available for co-deposition. These challenging tasks require optimisation of the process requirements and fundamental understanding of the interfaces between dissimilar materials, and will enable us to control and correlate the functional and structural properties of deposited layers.

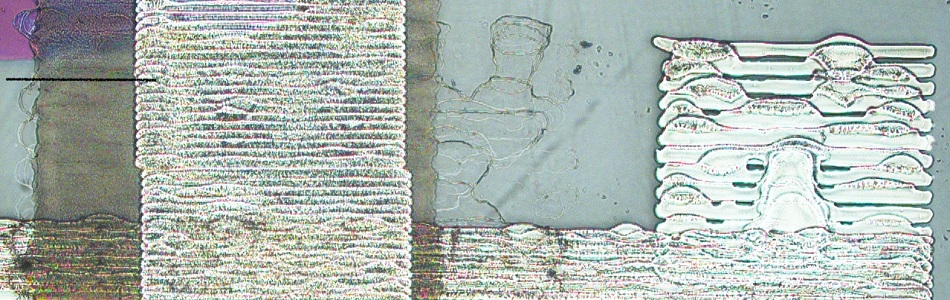

Exemplar arrangement of flakes used to predict conductivity characteristics of ink-jet printed graphene using a percolation Monte Carlo model

An encapsulated strain sensor made via multi-material inkjet 3D printing using UV conversion