Materials Characterisation and Structural Integrity

The UTC possesses world leading expertise in experimental materials characterisation and structural integrity assessment. Rather than adopting a “test house” approach in which routine experiments are performed using standard testing methods, the UTC group utilises a range of novel test frames and fixtures to expose materials to complex and representative load states and conditions, with advanced imaging and monitoring methods enabling the generation of high-quality data. The group specialises in high temperature and representative specimen testing methods and has worked in manufacturing process characterisation, impact and wear, and rate dependent material characterisation.

6X Denison Dead Weight Creep Test Frames

Constant load isothermal creep test frames, used for the study of long-term (week to month time scales) deformation and failure at elevated temperature.

Test types(s):

- Creep deformation and failure testing of metallic materials.

Key Testing Values:

- 100 kN

- Maximum testing temperature of 900°C

- Typical specimen dimensionsof 150 mm x 10 mm x 10 mm

4X Zwick-Roell High Temperature Uniaxial Test Frames

Test type(s):

- Isothermal mechanical testing (elasticity and material hardening). Elevated temperature small specimen testing.

Key Testing Values:

- 25 kN

- Maximum test temperature of 900°C

- Typical specimen dimensions of 150 mm x 10 mm x 10 mm

- Peak mechanical cycle rate of 30Hz.

Instron 8862 (TMF) Uniaxial Test Frame

A flexible and reconfigurable test frame, usually used for elevated temperature cycling and thermo-mechanical fatigue characterisation of materials. Fitted with external air cooling for aggressive thermal cycling.

Test types(s):

- An-isothermal material characterisation, crack propagation, and novel small specimen testing.

Key Testing Values:

- 35 kN

- Maximum test temperature of 1200°C

- Controlled heating rate of 15-20° C/s

- Typical specimen dimensions of160 mm x 8 mm x 8 mm

- Peak thermo-mechanical cycle rate of 30Hz.

Instron 1341 (HCF) Uniaxial Test Frame

Uniaxial room temperature high cycle testing of materials.

Test type(s):

- Crack initiation and high cycle fatigue damage characterisation of metallic materials.

Key Testing Values:

- 35 kN

- Typical specimen dimensions of 160 mm x 8 mm x 8 mm

- Peak mechanical cycle rate of 60Hz.

Lab Scale Inertia FrictionWelding (IFW) Machine

A miniature IFW test frame for the approximation of extreme manufacturing process load states.

Test type(s):

- Approximation of inertia frictionwelding manufacturing andprocess development.

Key Testing Values:

- 4 kN peak axial load

- Typical specimen dimensions of 80 mm x 25 mm (diameter)

- Peak rotational speed of 4140 rpm

- Flywheel energy of 4950 J

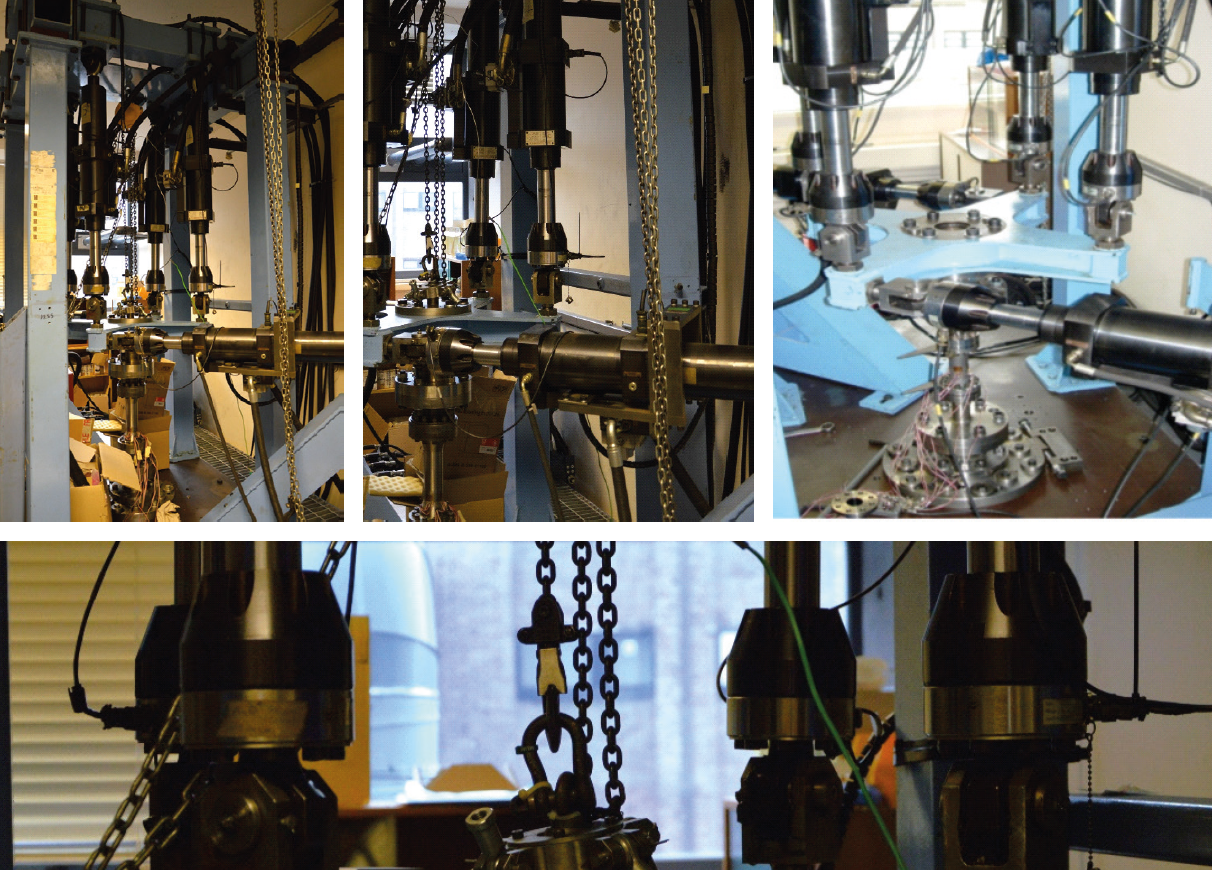

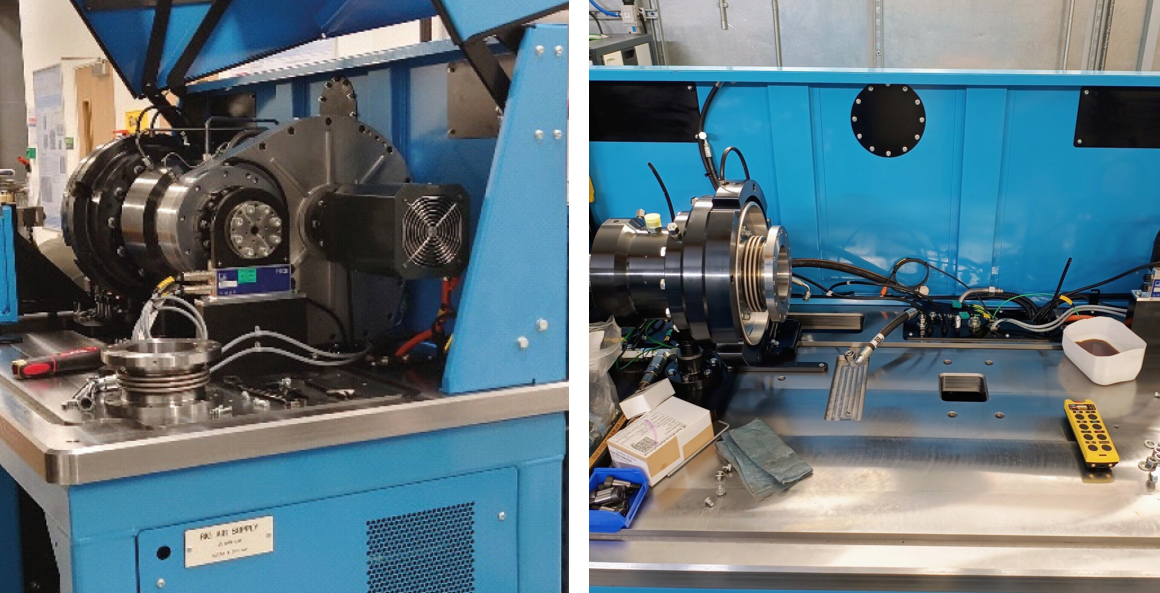

Tension-Torsion Multiaxial Test Frame

Application of system relevant loads to real components (spline connections and drive shafts) and the determination of critical buckling/failure modes.

Test type(s):

Key Testing Values:

- 100 kN axial loading

- 20kNm torque

- 1.6kNm rotating bending

- ±2kNm alternating torque

- 600mm specimen length (max.)

- 700 °C (max.)

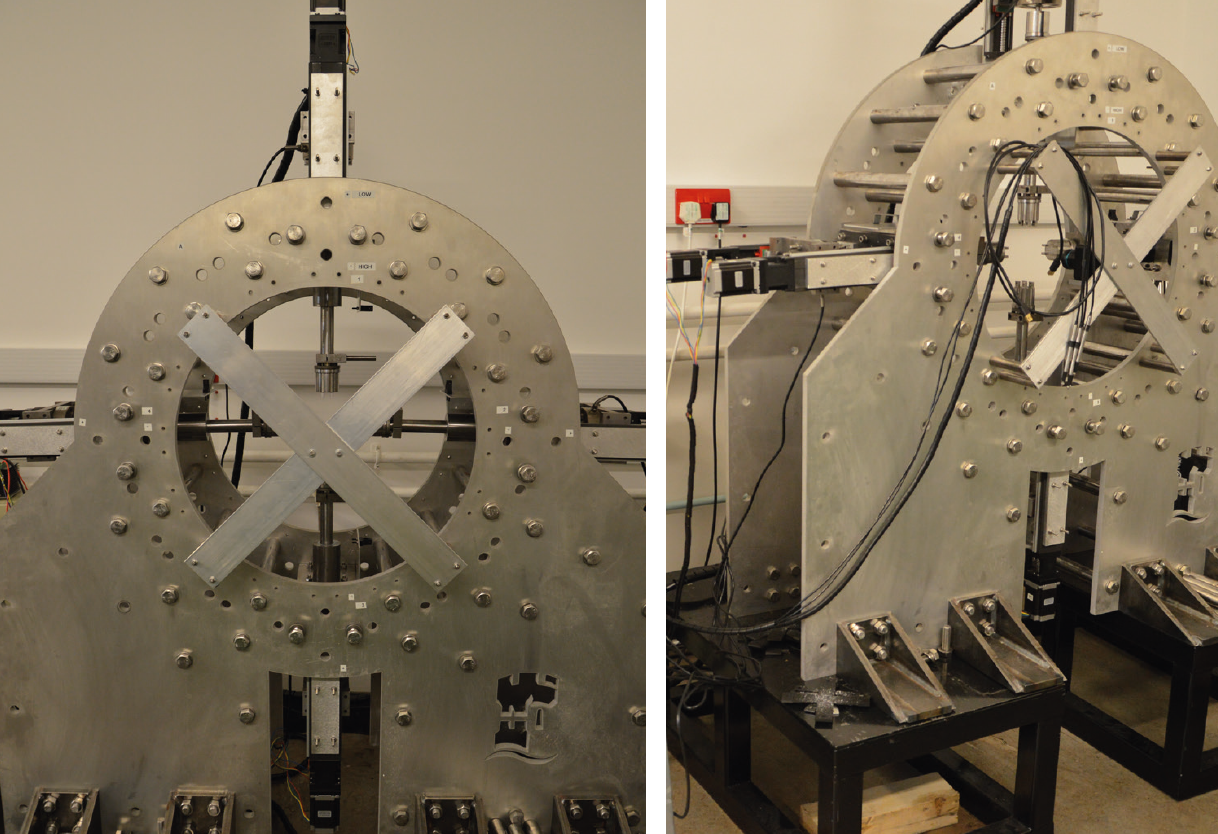

Bespoke Multiaxial Cruciform Test Frame

A bespoke biaxial test frame for the study of material anisotropy over amodest temperature range.

Test type(s):

- Anisotropy in additive manufacturing materials and composites.

Key Testing Values:

- 4x 4.4 kN actuator cassettes

- Test temperature range of –70 - +200°C

- Typical specimen dimensions of 150 mm x 150 mm x 4 mm (cruciform).

Instron High Temperature Uniaxial Test Frame

General and multipurpose uniaxial test frame for the study of monotonic (elastic-plastic) response of materials, with high temperature (isothermal) testing capability.

Test type(s):

- Isothermal mechanical testing (elasticity and material hardening). Elevated temperature small specimen testing and modest sized components.

Key Testing Values:

- 200 kN

- Maximum test temperature of 600°C

- Maximum specimen dimensions of 300 mm x 300 mm x 50 mm.

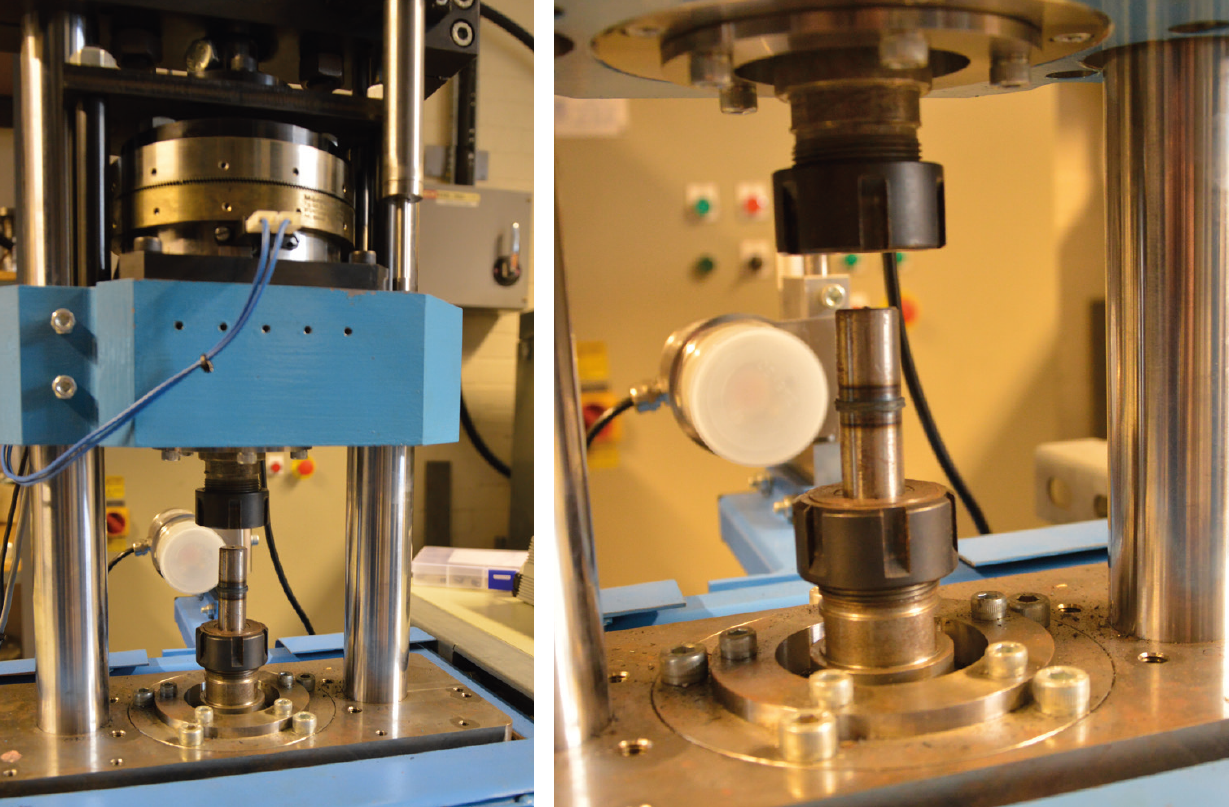

Bespoke Fretting Wear Test Frame

A dead-weight cyclic contact machine.

Test type(s):

- Fretting fatigue and wear in contactpairs and the evolution of friction.

Key Testing Values:

- Peak cyclic frequency of 100 Hz

- Typical tangential forces of 500 N

- Typical tangential strokesof 100 microns.

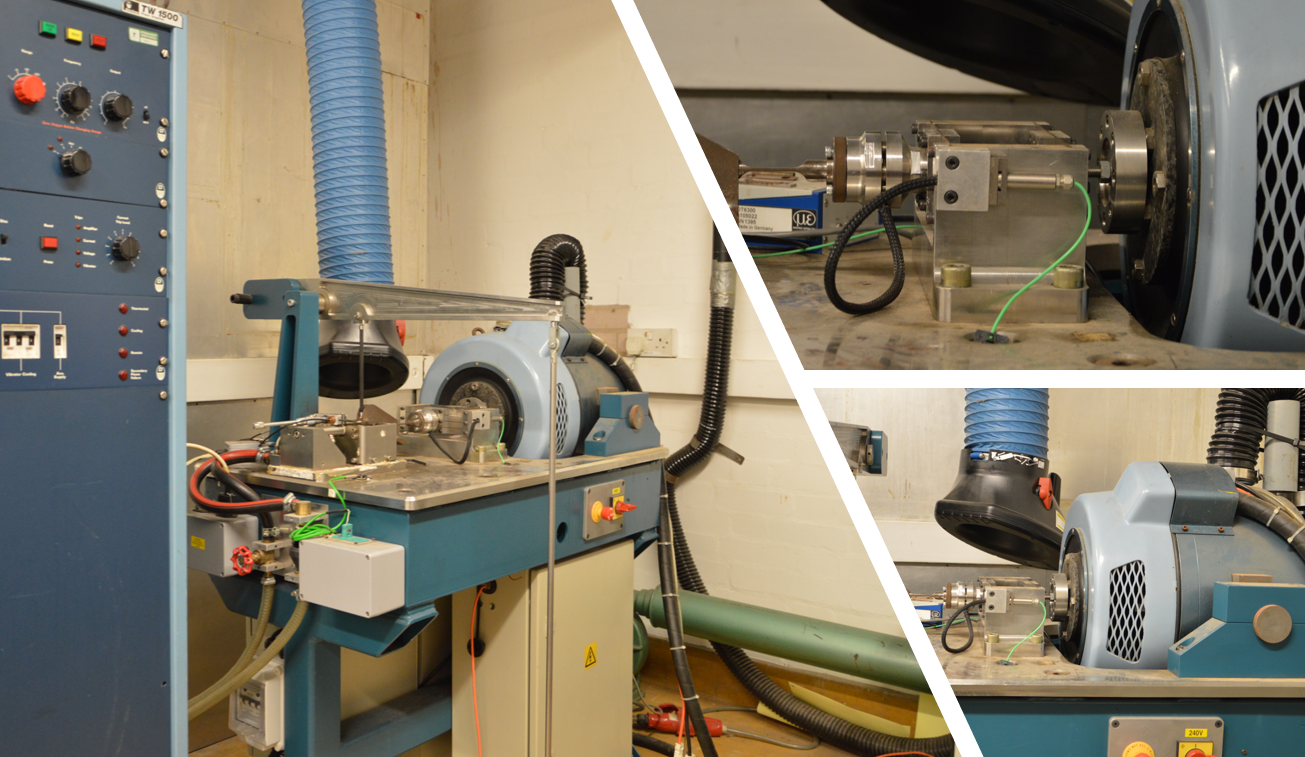

Angularly Misaligned Spine Coupling Test Rig

A test rig for investigating wear and fatigue in misaligned couplings.

Test type(s):

- Contact, Fretting, and Wear

Key Testing Values:

- Applied torque: 500Nm (max.)

- Misalignment: 0.75° (max.)

- Drive: 15,000 rpm (max.)