Rotordynamics and Electrification

The Transmissions UTC has the capabilities to explore the possible effects of wear, oil flow, and electrical discharges across differentbearing systems. Our rigs can control temperatures, bearing loadsand rotational speeds. The EMIF rig can inject shaft potentials at arange of frequencies up to 10 kHz, allowing for investigations intoelectromechanical interactions. Coupled with the UTC’s experienceand expertise, these facilities can be utilised in a wide range ofscenarios and applications.

AORBIT

The AORBIT rig is designed to investigate the use of hydrodynamic journal bearings in a large epicyclic gearbox. It has fully independent control of planet orbiting and rotational speeds with heated oil at a steady flow rate.

Test type(s):

- Journal bearings, coating wear

Key Testing Values:

- Carrier drive: 600 rpm

- Sun gear drive: 2500 rpm

- Journal gear coating thickness measurement equipment

- DAQ: speeds, torques, and temperatures continuously monitored.

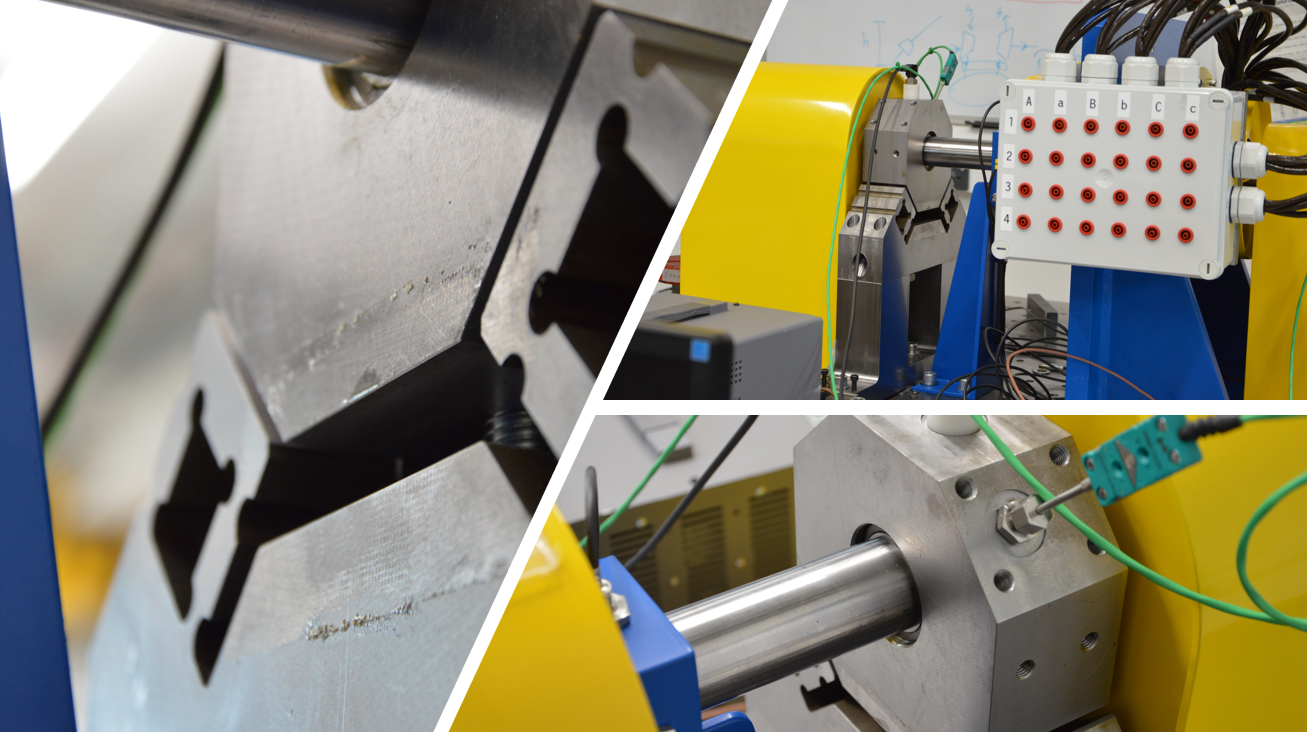

Electro-Mechanical Interactions Facility (EMIF)

EMIF has been developed to allow for the demonstration and exploitation of the electromechanicalinteractions of electrical machines. It is a functional and flexible test facilityrather than a specific test rig with limited scope for further expansion or investigations.It has been used to demonstrate rotordynamic control and investigate bearing arcing.

Test type(s):

- Electromechanical interactions,electrical arcing, unbalancedmagnetic pull (UMP), vibrations

Key Testing Values:

- 15,000 rpm (max.)

- Test motor test motor 600mm x 450mm each

- 200V (max.)